About Tube Mill Rolling Machine

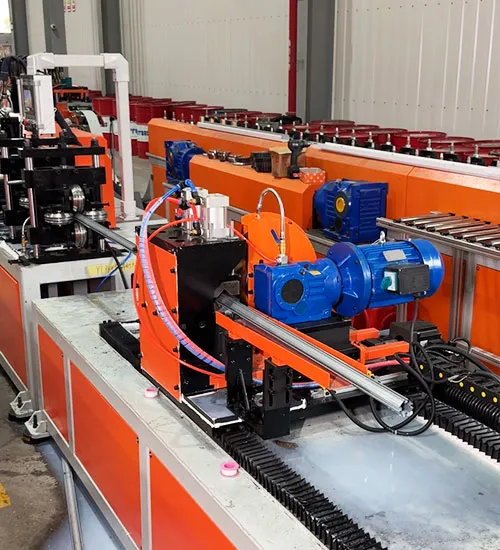

We provide complete, high-performance tube and pipe mills that integrate forming, laser welding, and cutting into one seamless process. Our systems are engineered for exceptional weld quality, dimensional accuracy, and high-speed operation, producing superior tubes for a wide range of industrial and structural applications.

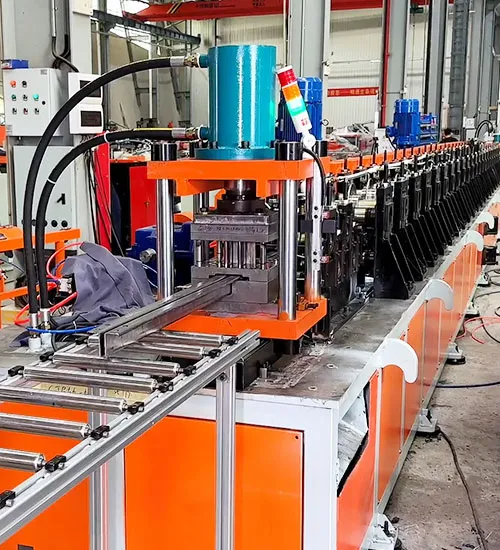

Cold Roll Forming Lines for Bed Frames & Support Beams

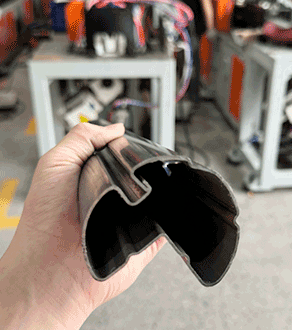

Produce durable and reliable steel bed frames, side rails, and support beams with our robust roll forming solutions. We can integrate processes like laser welding to create strong, closed-section tubes, ensuring the structural integrity and longevity required for both residential and commercial furniture applications like apartment beds.

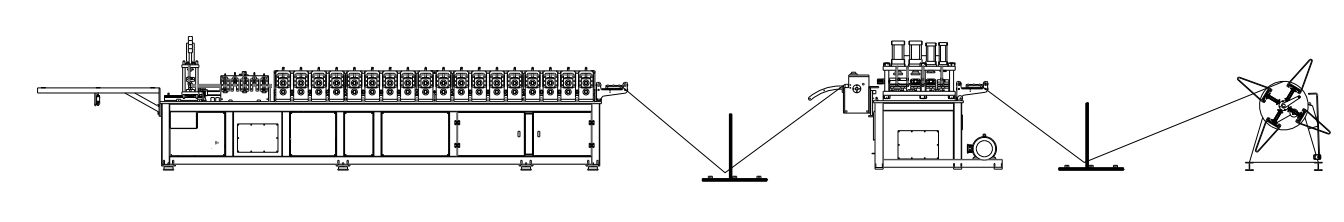

Bed Frames Roll Forming Making Line Process

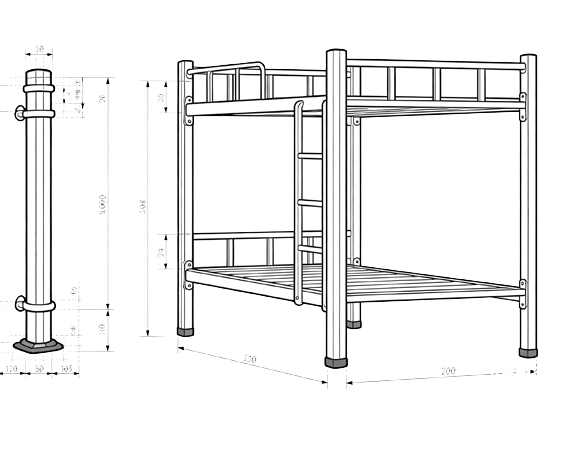

Show You The Support Beams Cases?

We can customize according to your requirements based on the load-bearing capacity, dimensions, and specifications needed for Support Beams. Here is a showcase of customizations we have made for Bed Frames factories.

Technology That Drives Your Competitive Edge

Armdax production lines are not just assemblies of standard parts; they are integrated systems featuring advanced technologies designed to maximize your productivity, flexibility, and profitability.

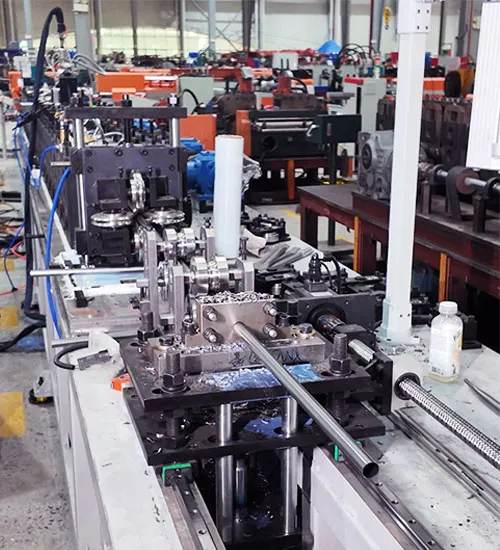

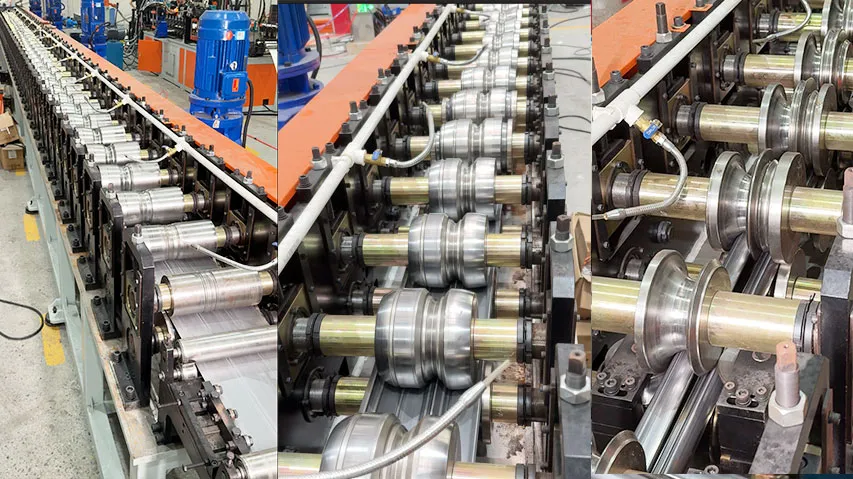

Precision Roll Forming System

Critical components are manufactured to the highest standards. Armdax Rollers are precision-machined on CNC lathes. Main shafts, are made from Cr12MoV alloy steel, tempered and precision-ground for maximum rigidity. The main frame side plates are machined from solid steel plates in a single setup on a CNC machining center to ensure perfect alignment.

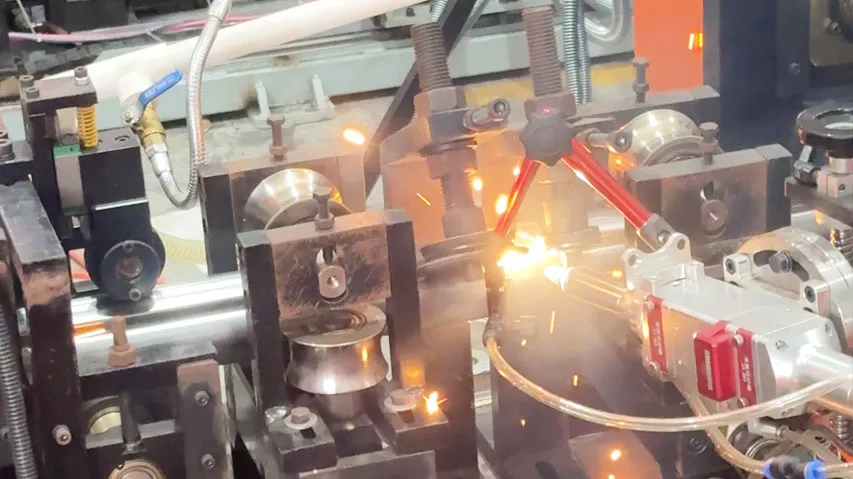

Automated Laser Welding System

ARMDAX welded bed support beam delivers uncompromising strength and durability. The laser welding creates a permanent, monolithic structure that effectively resists lateral forces and prevents rack sway. Each beam is accurately positioned and welded, ensuring perfect geometry and alignment for easy installation.The welded joint withstands the test of time, outperforming mechanical fasteners in demanding high-capacity environments.

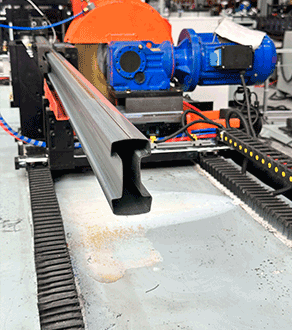

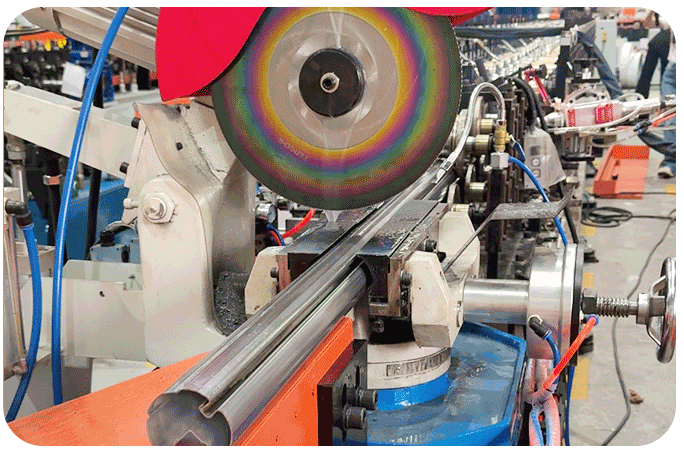

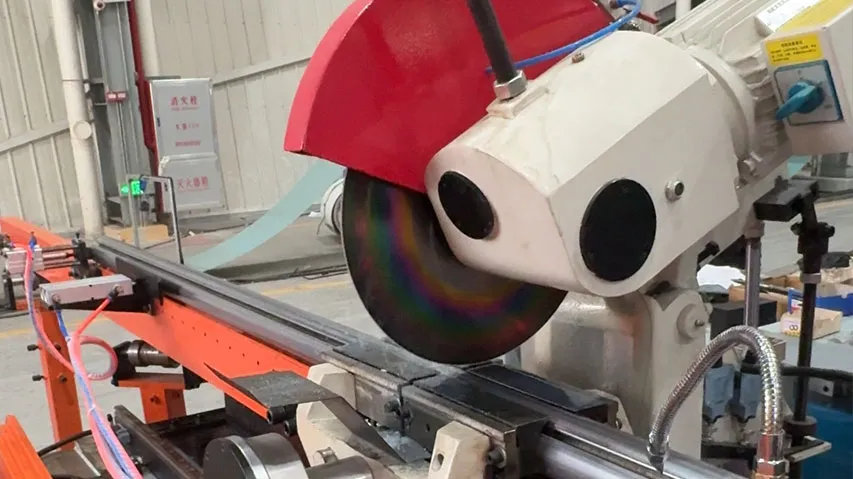

Chainsaw Cutting Revolutionizes

ARMDAX chainsaw cutting system delivers clean, burr-free cuts in seconds—without stopping the roll forming line. Perfectly synchronized with continuous roll forming for non-stop production of bed support beams. Clean cuts maintain structural integrity, ensuring reliable and durable beams. Minimize waste, reduce downtime, and maximize output with high-speed automation.

Engineered for Peak

Performance and Precision

Every component and parameter of our production line is designed and specified to deliver consistent, high-quality output.

| Product Material: | Material Thickness: |

| Product Width Range: | Margin of error: |

| Drive System: | Form speed: |

| Control System: | Roller material: |

Download Full Technical Proposal

Download Full Technical ProposalYou Might Also Like

Ready to Optimize Your Production?

FAQS

Q: Can ARMDAX customize square pipe roll forming lines?

A:

Yes. ARMDAX customizes square pipe, round pipe and shaped-tube roll forming production lines with forming, welding, sizing, and cutting systems based on pipe diameter and thickness.

Q: What is your after-sales repair policy about cold roll forming machines?

A:

We provide a one-year warranty for the entire machine. For key components such as the main unit, servo motors, and CNC controllers—excluding consumable parts (tools) from warranty coverage—if any non-human-caused malfunction occurs, we will immediately ship replacement parts free of charge via DHL/FedEx.

Q: How much does a roll forming machine cost ?

A:

Different industries and different product sizes will affect the price of the machine. We customize solutions based on the your drawings and then calculate the price. We have a professional set of customization and production processes. Do you want to know the price of a roll forming machine , click this blogs maybe can help you understand.

Q: What is the maximum material thickness and width your roll forming machines can handle?

A:

ARMDAX roll forming machines are built to handle a wide range. Typically, we work with material thicknesses from 0.2mm to 5 mm and coil widths can be adjustable. However, specific capabilities depend on the profile design and material strength. Our engineers will provide exact specifications after reviewing your requirements.