What Factors Influence the Costs of Storage Rack Roll Forming Machine

Nov 14, 2025

Read:205

Source: Armdax

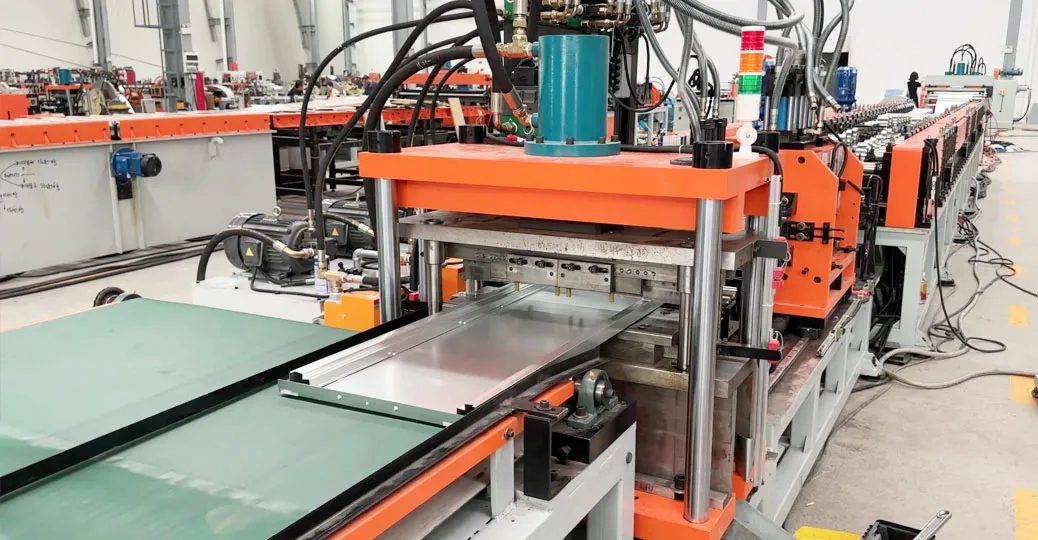

Understanding Storage Rack Roll Forming Machine Costs: A Comprehensive Guide

As a leading manufacturer with 20 years of experience in storage rack roll forming machinery, ARMDAX frequently encounters one key question: "How much does a storage rack roll forming machine cost?" The truth is, pricing varies significantly based on several crucial factors. Let's break down what influences the final investment.

Key Factors Determining Roll Forming Machine Costs

1. Machine Materials & Construction Quality

Frame Materials: Heavy-duty steel frames cost more but ensure longer lifespan

Roller Quality: CR12MOV alloy steel rollers vs standard steel components

Surface Treatment: Premium corrosion protection adds 15-25% to baseline cost

Electrical Components: Siemens/Japanese brands vs local alternatives affect pricing

2. Brand Value & Technical Expertise

20 Years Specialization: ARMDAX's proven track record in storage rack systems

R&D Investment: Continuous innovation in automation technology

Quality Certifications: ISO 9001, CE certification ensuring international standards

After-sales Service: Comprehensive support network across global markets

3. Customization Level & Technical Requirements

Profile Complexity: Simple C-beams vs complex box beam designs

Production Speed: Standard (15-20 m/min) vs high-speed (25-30 m/min) systems

Automation Level: Basic vs fully automated lines with robotic integration

Additional Features: In-line punching, notching, or welding stations

Why ARMDAX Delivers Superior Value

Proven Industry Leadership

*Ranked among China's top 3 storage rack machinery manufacturers

*500+ successful installations worldwide

*Continuous operation records exceeding 100,000 hours

Advanced Smart Manufacturing

*IoT-enabled production monitoring systems

*Predictive maintenance technology

*Real-time performance optimization

*Remote technical support capabilities

Custom Engineering Excellence

*Dedicated project engineering team

*3D simulation before manufacturing

*Material optimization consulting

*Factory acceptance testing included

Cost vs. Return on Investment Analysis

Initial Investment Range:

Basic semi-automatic lines: $80,000 - $150,000

Standard automated systems: $150,000 - $300,000

Fully customized high-speed lines: $300,000 - $600,000+

Long-term Value Proposition:

40-60% labor cost reduction

3-5 year return on investment

30% higher production efficiency

50% reduction in material waste

The ARMDAX Advantage: More Than Just Equipment

Our clients choose ARMDAX not just for the machinery, but for the complete solution:

*Comprehensive Support Services

*Free initial consultation and layout planning

*On-site installation and commissioning

*Operator training programs

*24-month warranty period

*Lifelong technical support

Success Stories

*Brazilian Client: Achieved 400% production increase within 6 months

*Indian Manufacturer: Reduced labor costs by 70% while improving quality

*Australian Distributor: Expanded product range with custom profile capabilities

Next Steps: Getting Your Custom Quote

The exact cost of your storage rack roll forming machine depends on your specific requirements. Here's our transparent process:

1.Share Your Requirements: Provide profile drawings and production goals

2.Technical Analysis: Our engineers assess feasibility and optimize design

3.Detailed Proposal: Receive comprehensive solution with exact pricing

4.Factory Visit: See similar machines in operation (virtual tour available)

Ready to Transform Your Storage Rack Production?

Contact ARMDAX today for a personalized cost analysis. Our experts will provide:

*Detailed machine specifications

*Customized investment plan

*ROI calculation specific to your operation

*References from satisfied global clients

Don't just buy a machine - invest in a partnership with 20 years of expertise. Let ARMDAX help you build the future of yourstorage rack manufacturing business.

Table of Contents