About Building & Construction Making Line

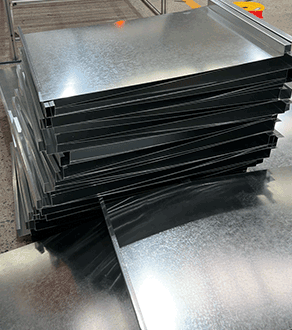

We engineer robust, high-output roll forming lines for the demanding construction industry. Our solutions transform galvanized steel and other materials into durable structural components, from ceiling grids to wall panels. Built for reliability, our machines ensure the production of precise, weather-resistant profiles that meet stringent industry standards.

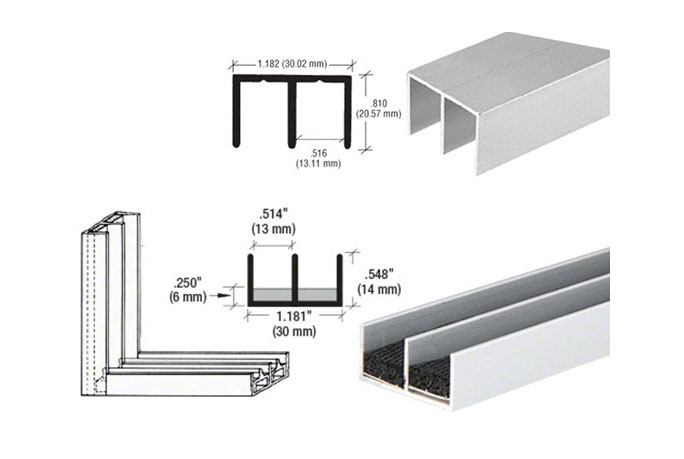

High quality Roll Forming Lines for Window Frames

Elevate your window manufacturing with our industry-leading roll forming lines, designed to deliver unmatched precision, speed, and reliability. From initial consultation and custom line design to comprehensive installation, training, and lifetime support, we are dedicated to optimizing your production and profitability.

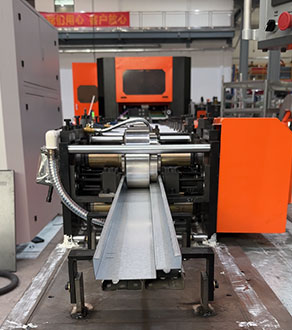

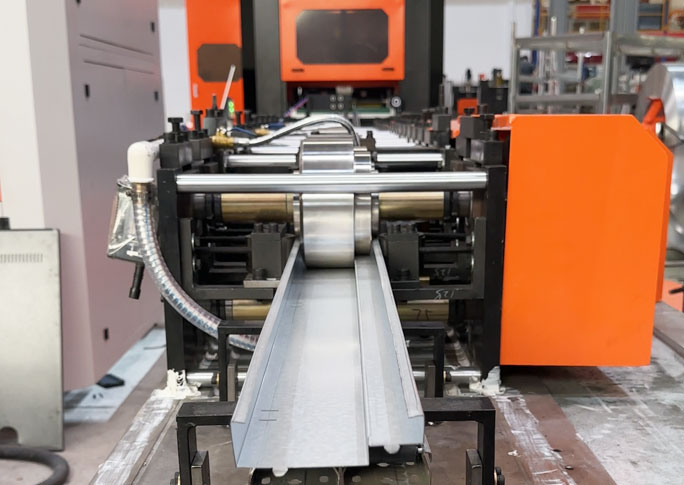

The process in Coil Laser Cutting & Roll Forming Machine

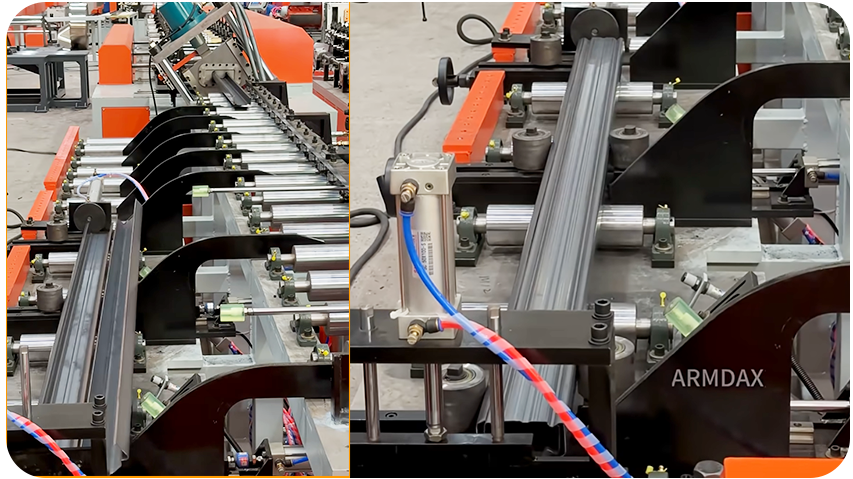

Show the Window & Door frame production Cases

We can customize according to your requirements based on the load-bearing capacity, dimensions, and specifications needed for wall & roof panels. Here is a showcase of customizations we have made for building making line.

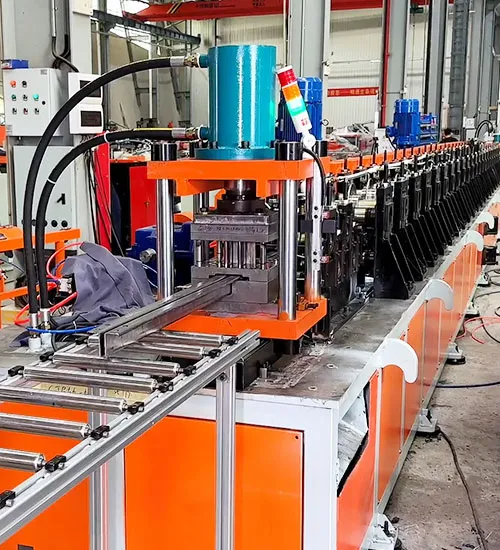

Technology That Drives Your Competitive Edge

Our production lines are not just assemblies of standard parts; they are integrated systems featuring advanced technologies designed to maximize your productivity, flexibility, and profitability.

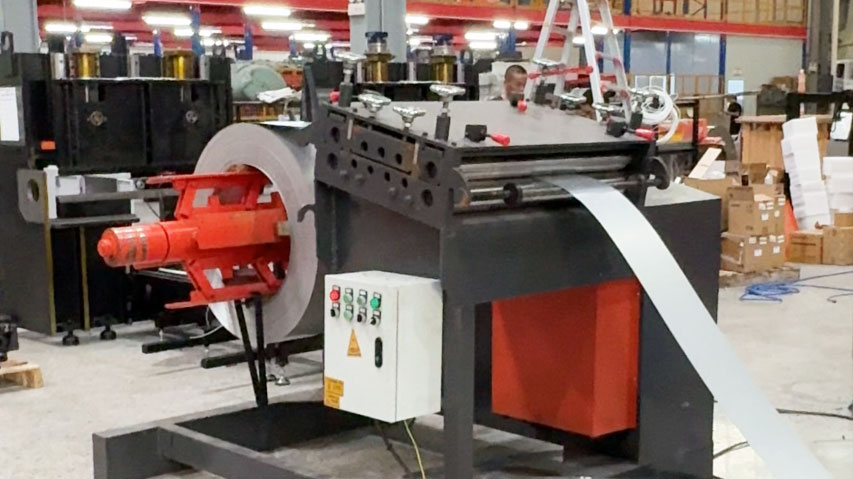

Coil Feeding & Leveling

Every great roll-formed product begins with a perfect start. Our automated coil feeding and precision leveling machines are the unsung heroes of your production line, ensuring consistent quality from the very first meter.

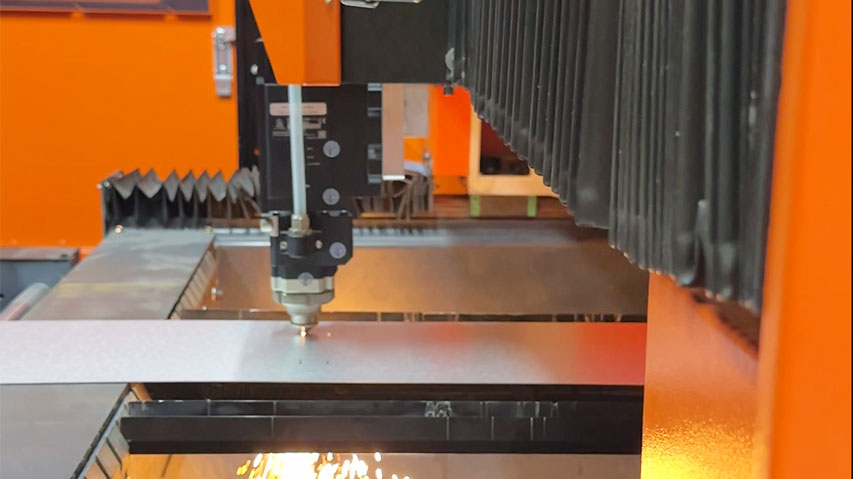

Laser cutting machine

This production line is specifically designed for high-efficiencysheet metal processing. It seamlessly uncoils, levels, and feedscold-rolled steel, galvanized steel, stainless steel, and other coilmaterials directly into a laser cutting system, producing custom-sized plates in a single, integrated operation. The entire systemis centrally controlled by a CNC system, which utilizes servomotors and high-precision ball screws to ensure accurate feedlength control. This significantly enhances cutting efficiency anddrastically reduces traditional plate loading time.

Uncompromising Precision in Manufacturing

Critical components are manufactured to the highest standards. Rollers are precision-machined on CNC lathes. Main shafts, are made from Cr12MoV alloy steel, tempered and precision-ground for maximum rigidity. The main frame side plates are machined from solid steel plates in a single setup on a CNC machining center to ensure perfect alignment.

Engineered for Peak

Performance and Precision

Every component and parameter of our production line is designed and specified to deliver consistent, high-quality output.

| Product Material: | Material Thickness: |

| Product Width Range: | Margin of error: |

| Drive System: | Form speed: |

| Control System: | Roller material: |

Download Full Technical Proposal

Download Full Technical ProposalYou Might Also Like

Ready to Optimize Your Production?

FAQS

Q: What thickness range can ARMDAX purlin roll forming machines process?

A:

ARMDAX purlin roll forming machines are suitable for steel thickness from 0.2mm to 5mm, meeting most structural steel building requirements.

Q: Are ARMDAX roofing roll forming machines suitable for different markets?

A:

Yes. ARMDAX roofing roll forming machines are designed for different international standards, including profiles popular in the USA, Middle East, Africa, and Southeast Asia markets.

Q: What is the maximum speed and output of your machines?

A:

Armdax roll forming machines have a line max speed up to 35 meters per minute. The actual output depends on the profile complexity and operator efficiency.

Q: What kind of control system do you use?

A:

We use internationally renowned PLC systems (like Siemens or Mitsubishi) with a user-friendly touchscreen interface. This allows for precise control over speed, length, and production count.