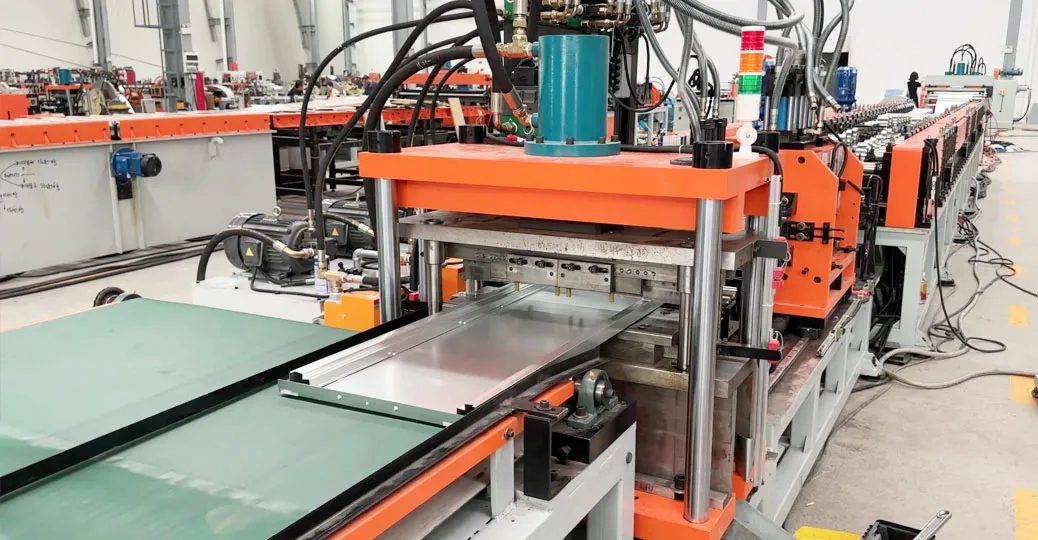

How to Choose the Right Roll Forming Machine for Your Factory: The Ultimate Guide

Aug 25, 2025

Read:368

Source: Armdax

Investing in a roll forming machine is a significant decision that can revolutionize your factory's productivity and profitability. However, with various models and configurations available, selecting the right one can be a complex task. Choosing incorrectly can lead to production bottlenecks, inconsistent quality, and wasted capital.

This comprehensive guide will walk you through the critical factors you must consider to choose the perfect roll forming machine that meets your specific production needs and delivers a strong return on investment (ROI).

1. Define Your Product Requirements

This is the foundation of your decision. The machine must be capable of producing your specific profile.

Profile Geometry & Complexity: What is the final cross-sectional shape? Is it a simple C-channel or a complex custom design with multiple bends? Complex profiles require more forming stations (stands).

Material Type & Thickness: What material will you be forming? (e.g., galvanized steel, aluminum, copper). Crucially, what is the thickness range (e.g., 0.3mm to 2.0mm)? The machine must be built to handle your material's yield strength and thickness.

Final Product Length: What are the minimum and maximum lengths of your finished product? This determines the required cutting system (e.g., flying cut-off saw).

2. Evaluate Production Capacity & Speed

Your required output directly influences the machine's specifications and cost.

Line Speed: Measured in meters or feet per minute. How fast do you need to produce the profile? High-volume factories will prioritize speed (e.g., 25+ m/min), while smaller shops may opt for a more economical, slower model.

Automation Level: Will you need a fully automated line with an automatic decoiler, pre-punching stations, and stackers? Or will a basic machine with manual feeding suffice? Automation boosts output and reduces labor but increases the initial investment.

3. Understand Key Machine Components & Quality

The quality of the machine's components dictates its durability, precision, and longevity.

Forming Stations & Rollers: The number of stations determines the complexity of profiles that can be formed. The rollers should be made from high-quality, hardened alloy steel (e.g., Cr12, 42CrMo) and precision-ground for a long service life and smooth surface finish.

Control System: A modern PLC (Programmable Logic Controller) with a touchscreen HMI (Human-Machine Interface) is essential for easy operation, precise control, and troubleshooting. Look for user-friendly software.

Structural Frame: The machine frame must be robust and rigid to withstand constant vibration and force, ensuring consistent precision over time.

4. Consider Customization and Flexibility

Think about your future needs, not just your current ones.

Quick-Change Tooling: If you produce multiple profiles, a system that allows for rapid roller changes is invaluable for minimizing downtime.

Future-Proofing: Can the machine be easily upgraded or modified for new profiles? A supplier who offers customizable solutions is a significant advantage.

5. Assess the Manufacturer and After-Sales Support

The machine is only as good as the company behind it.

Manufacturer vs. Trader: Always prefer a direct manufacturer. They have deeper technical expertise, better control over quality, and can provide more competitive pricing.

Technical Support & Training: Does the supplier offer comprehensive installation, training, and trcoubleshooting support?

Spare Parts Availability: Ensure that spare parts are readily available. Ask about their policy and lead times for critical components.

Warranty: A clear and reasonable warranty period reflects the manufacturer's confidence in their product.

6. Analyze the Total Cost of Ownership (TCO)

Look beyond the initial purchase price.

Initial Investment: The cost of the machine and tooling.

Operating Costs: Energy consumption, labor, and routine maintenance.

Downtime Costs: A reliable machine from a reputable supplier minimizes costly production stoppages.

A higher-quality machine may have a higher upfront cost but a lower TCO due to better reliability and efficiency.

Checklist: Key Questions to Ask Your Supplier

Before you make a final decision, get clear answers to these questions:

Can you build a machine for my specific profile and material?

What is the expected tooling life, and what is the cost for spare rollers?

Can you provide a video of a similar machine running in a factory?

What is included in the price? (e.g., installation, training, shipping)?

What is your lead time for production and delivery?

Can you provide references from other clients in my industry?

Conclusion

Choosing the right roll forming machine is a strategic investment that requires careful analysis of your product, production goals, and budget. By thoroughly evaluating these factors and partnering with a reliable, experienced manufacturer, you can equip your factory with a machine that will drive your growth and success for years to come.

Ready to Find Your Perfect Roll Forming Solution?

Contact us today for a free, no-obligation consultation! Our engineering experts will analyze your requirements and provide a tailored solution to maximize your factory's efficiency.

Table of Contents