The Best Sheet Metal Roll Forming Machine for Sale in 2026

Dec 01, 2025

Read:153

Source: Armdax

The Evolution of Sheet Metal Automation

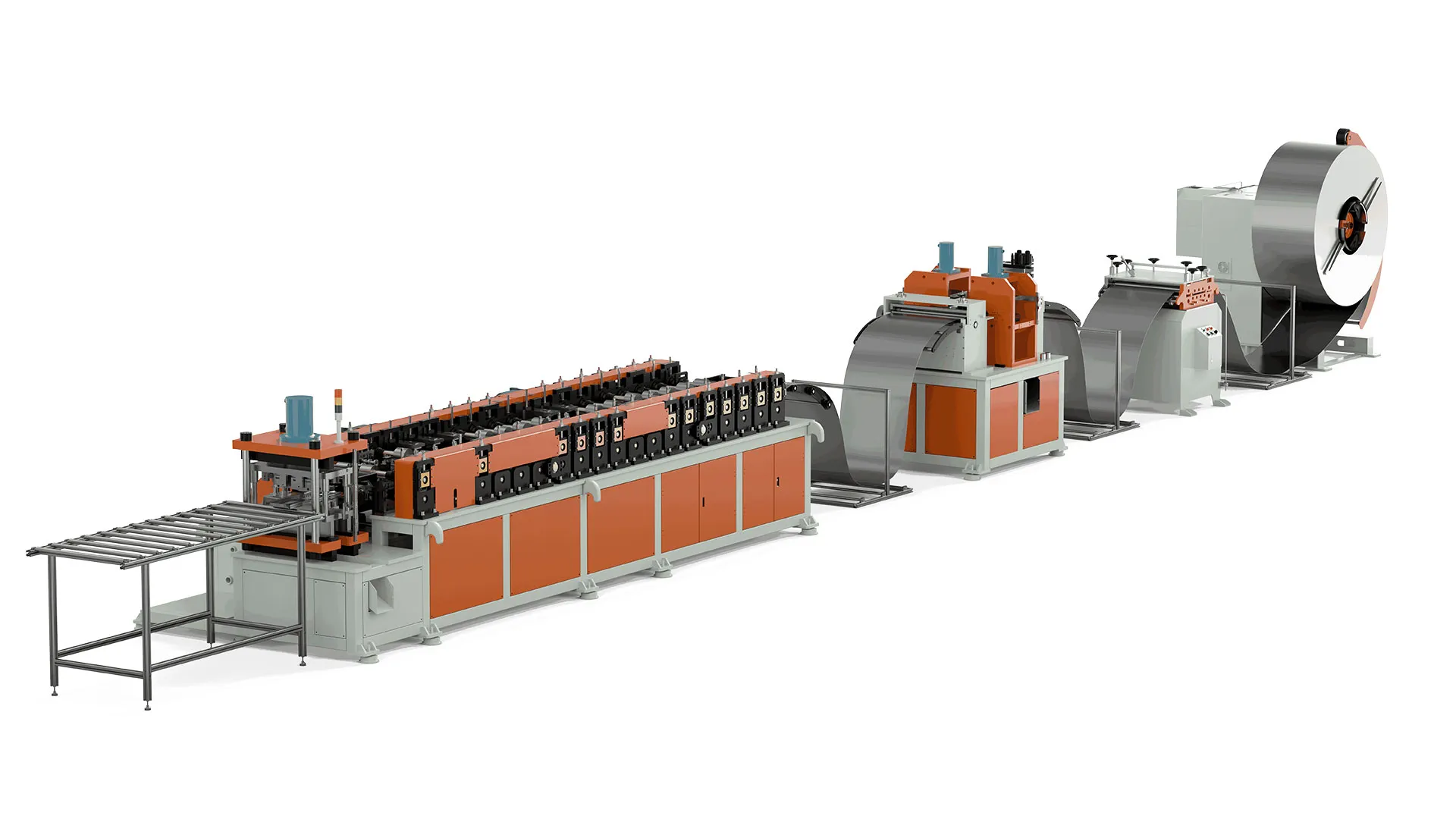

As we approach 2026, the sheet metal fabrication industry stands at the threshold of unprecedented technological transformation. Manufacturers worldwide face increasing demands for higher precision, faster production cycles, and smarter automation solutions. In this evolving landscape, one company has consistently demonstrated the expertise and innovation to meet these challenges head-on: ARMDAX.

With over two decades of specialized experience in roll forming technology, ARMDAX has established itself as a visionary leader committed to advancing metal fabrication through continuous research, development, and engineering excellence. Here is the best sheet metal roll forming machine for sale in 2026.

Why ARMDAX Stands Out in 2026

Proven Legacy with Future-Ready Technology

20+ years of focused expertise in roll forming machinery

Ongoing R&D investment exceeding industry standards

Patented technologies in precision forming and automation

Global installation and support network

Innovative Features for Modern Manufacturing

1. Smart Control Systems

AI-powered optimization algorithms

Real-time production monitoring and analytics

Predictive maintenance capabilities

Remote diagnostics and troubleshooting

2.Advanced Material Handling

Automated coil loading and feeding systems

Integrated quality inspection modules

Intelligent material tracking and management

Adaptive forming parameter adjustment

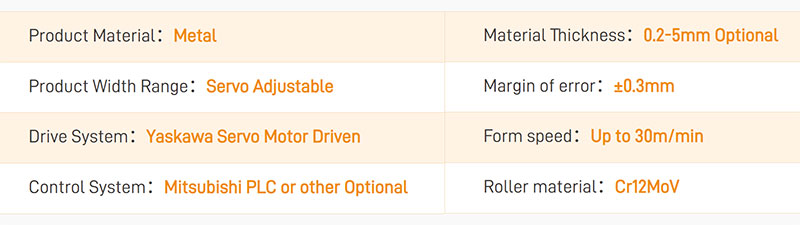

3.Precision Engineering

Sub-millimeter forming accuracy (±0.05mm)

High-speed operation up to 45 meters/minute

Quick-change tooling systems (under 5 minutes)

Energy-efficient servo motor technology

The ARMDAX Advantage: Beyond Equipment

Comprehensive Solutions for Global Manufacturers

ARMDAX understands that successful automation requires more than just machinery. Our approach includes:

Custom Engineering: Every system is tailored to your specific production requirements

Turnkey Implementation: Complete installation, commissioning, and training

Lifelong Support: 24/7 technical assistance and spare parts availability

Continuous Upgrades: Regular software and hardware enhancements

Sustainable Manufacturing Focus

30% reduction in energy consumption versus traditional systems

Minimal material waste through optimized forming processes

Extended equipment lifespan through superior construction

Compliance with global environmental standards

Industry Applications Revolutionized by ARMDAX

Building and Construction

*Structural steel components

*Roofing and wall panels

*Window and door frames

*HVAC ducting systems

Automotive and Transportation

*Vehicle frame components

*Ship panel reinforcements

*Storage compartment systems

*Custom trailer fabrication

Industrial Equipment

Machinery enclosures

Storage systems and shelving

Conveyor components

Equipment housings

What Makes ARMDAX Machines the Best Choice for 2026?

Unmatched Technical Specifications

Global Success Stories

*North American Client: Achieved 400% production increase within 8 months

*European Manufacturer: Reduced labor costs by 65% while improving quality control

*Asian Partner: Expanded product range to include 15 new custom profiles

*Middle Eastern Operation: Implemented fully automated 24/7 production facility

Future-Ready Technology for 2026 and Beyond

ARMDAX is already developing next-generation technologies for the coming decade:

1.IoT Integration

Complete digital twin implementation

Real-time production data analytics

Automated quality assurance systems

2.Advanced Materials Compatibility

High-strength steel alloys

Composite materials

Specialty coated metals

3.Sustainable Manufacturing

Circular economy integration

Zero-waste production targets

Carbon-neutral operations

How to Select Your Perfect Roll Forming Solution

Key Considerations for 2026

Production volume requirements

Material specifications and variations

Space and facility constraints

Future expansion plans

Technical support availability

ARMDAX Roll Forming Machine Selection Process

1.Needs Analysis: Comprehensive evaluation of your requirements

2.System Design: Custom engineering and simulation

3.Proposal Development: Detailed technical and financial planning

4.Implementation: Professional installation and training

5.Optimization: Continuous performance improvement

Conclusion: Partner with the Future of Sheet Metal Fabrication

As we look toward 2026, the choice of manufacturing equipment has never been more critical. ARMDAX represents more than just machinery – we offer a partnership in progress, a commitment to excellence, and a pathway to manufacturing leadership.

Our vision extends beyond selling equipment; we are dedicated to empowering metal fabricators worldwide with the tools, technology, and support needed to thrive in an increasingly competitive global market. With over 20 years of experience and unwavering commitment to innovation, ARMDAX is poised to help manufacturers not just meet the challenges of 2026, but to define the standards of excellence for the entire industry.

Ready to Transform Your Manufacturing Capabilities?

Contact ARMDAX today to schedule a consultation with our engineering team. Discover how our advanced roll forming solutions can position your business for success in 2026 and beyond.

Table of Contents