About Racking & Shelving Machine

ARMDAX design and manufacture turnkey roll forming lines for manufacturing shelf panels , rack uprights,P-beams and Bracings. Our systems integrate Uncoiling feeding →leveling →punching system →roll forming-automatic cutting - flanging - finished product , to produce a wide range of profiles, from heavy-duty industrial racks to retail shelving. Achieve high-speed production, exceptional precision, and rapid changeovers with robust, automated solutions engineered for maximum uptime and profitability.

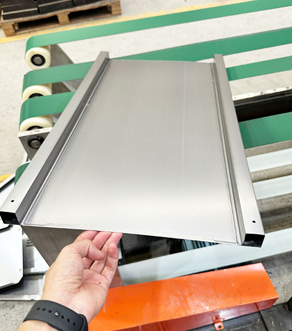

Shelving Panel Production Line for High-Volume Manufacturing

Achieve Consistent Quality and High Throughput with a Robust, PLC-Controlled Shelving Rack Panels Roll Forming System, Engineered for Continuous, High-Speed Operation.

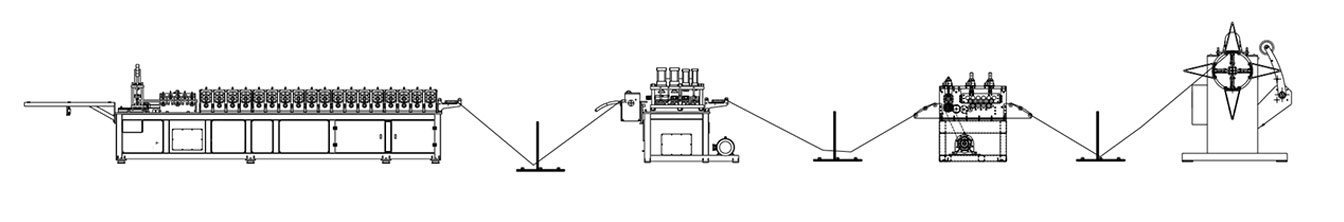

Automated Panel Roll Forming Production Line Process

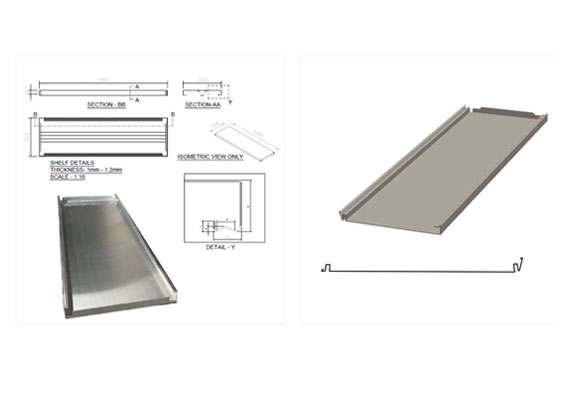

Related Panels Production Cases Display

We can customize according to your requirements based on the load-bearing capacity, dimensions, and specifications needed for metal sheet storage rack panels. Here is a showcase of customizations we have made for shelving factories.

Precision Engineering, Powered by ARMDAX

Our production lines are not just assemblies of standard parts; they are integrated systems featuring advanced technologies designed to maximize your productivity, flexibility, and profitability.

Servo-Driven Width Adjustment

The roll forming stands are equipped with a high-precision servo motor that automatically adjusts the horizontal position of the rollers. This allows the production line to switch between different shelf panel widths (e.g., 175mm, 400mm, 800mm, 1200mm) by simply entering new parameters on the HMI. No lengthy manual mechanical adjustments are required.

Fully Integrated Intelligent Control System

The entire line is controlled by a central PLC, managed through an intuitive HMI touch screen. All production parameters—including length, quantity, and punching patterns—are stored as recipes and can be recalled with a single touch. The system provides real-time diagnostics and production data tracking. Simplify operations and reduce reliance on highly skilled operators. The user-friendly interface minimizes the learning curve and reduces the chance of human error, ensuring consistent, high-quality output regardless of the operator. Faster job setup and real-time monitoring lead to increased overall equipment effectiveness (OEE).

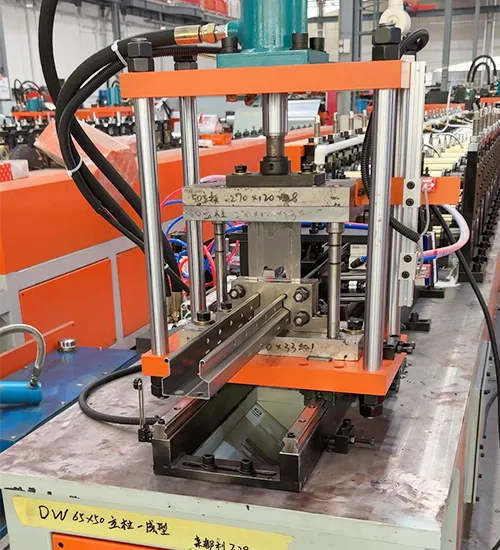

Perfect Hydraulic Punching System

Armdax punch precise holes for clips and connectors directly in the forming process. Eliminate costly secondary operations. Hydraulic force delivers clean, burr-free holes in heavy-duty steel, ensuring perfect structural integrity. And Easily adapt punching patterns for different shelf models with quick tooling changes, which perfect for custom orders.

Engineered for Peak

Performance and Precision

Every component and parameter of our production line is designed and specified to deliver consistent, high-quality output.

| Product Material: | Material Thickness: |

| Product Width Range: | Margin of error: |

| Drive System: | Form speed: |

| Control System: | Roller material: |

Download Full Technical Proposal

Download Full Technical ProposalYou Might Also Like

Ready to Optimize Your Production?

FAQS

Q: Can ARMDAX customize roll forming machines for storage racking profiles?

A:

Yes. ARMDAX provides customized racking roll forming machines based on load requirements, profile thickness, hole patterns, and international racking standards, ensuring high precision and repeatability.

Q: What types of racking roll forming machines does ARMDAX supply?

A:

ARMDAX supplies heavy-duty racking roll forming machines for pallet racking, selective racking, drive-in racking, and warehouse storage systems, with optional inline punching and servo cutting systems.

Q: What is your after-sales repair policy about cold roll forming machines?

A:

We provide a one-year warranty for the entire machine. For key components such as the main unit, servo motors, and CNC controllers—excluding consumable parts (tools) from warranty coverage—if any non-human-caused malfunction occurs, we will immediately ship replacement parts free of charge via DHL/FedEx.

Q: What is the maximum material thickness and width your roll forming machines can handle?

A:

ARMDAX roll forming machines are built to handle a wide range. Typically, we work with material thicknesses from 0.2mm to 5 mm and coil widths can be adjustable. However, specific capabilities depend on the profile design and material strength. Our engineers will provide exact specifications after reviewing your requirements.