About Racking & Shelving Machine

ARMDAX design and manufacture turnkey roll forming lines for manufacturing shelf panels , rack uprights,P-beams and Bracings. Our systems integrate Uncoiling feeding →leveling →punching system →roll forming-automatic cutting - flanging - finished product , to produce a wide range of profiles, from heavy-duty industrial racks to retail shelving. Achieve high-speed production, exceptional precision, and rapid changeovers with robust, automated solutions engineered for maximum uptime and profitability.

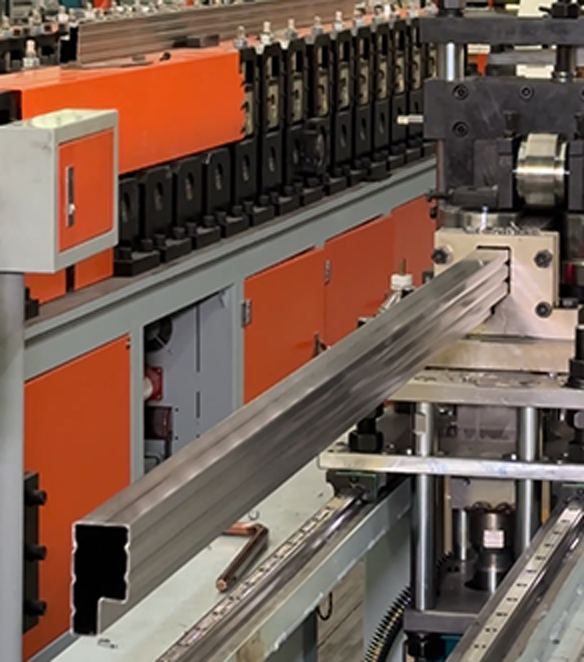

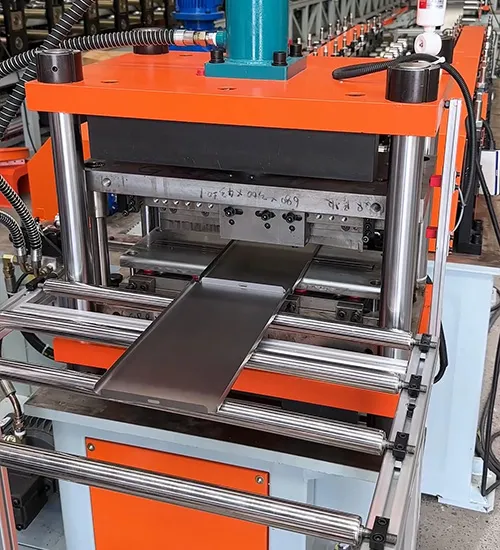

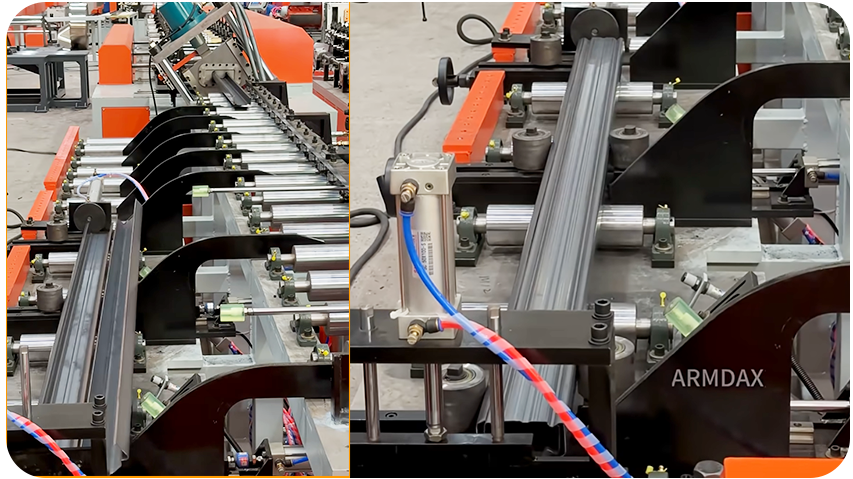

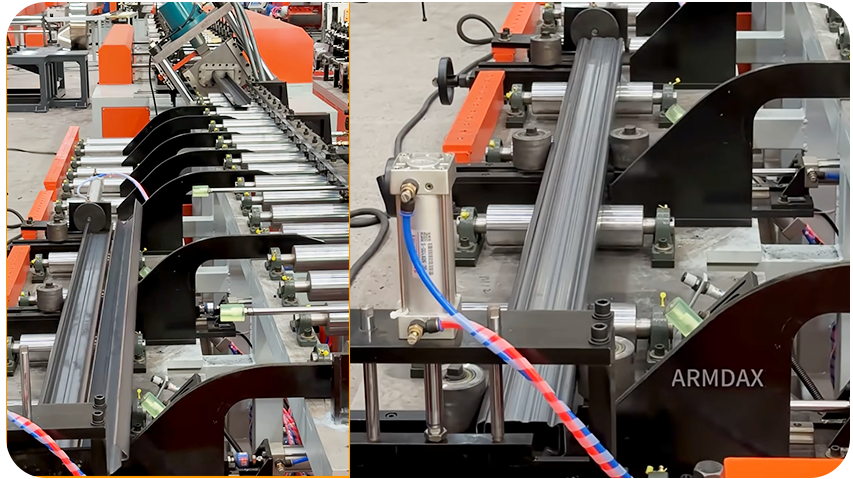

Automated Racking P-beams & box beams Making Machine

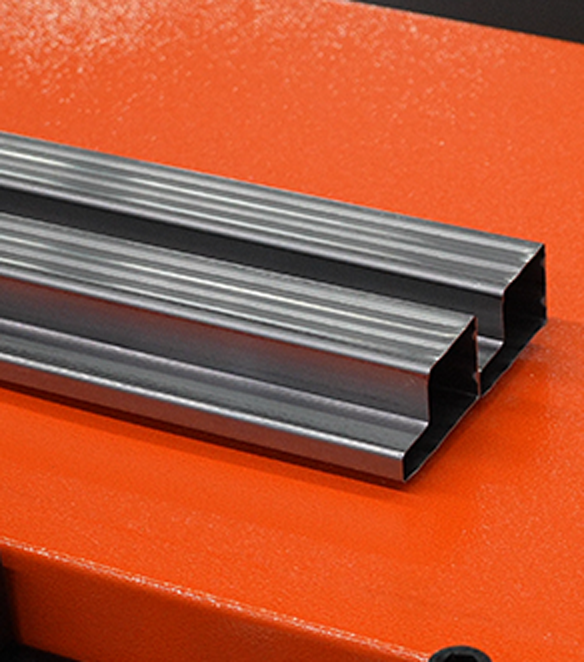

We provide turnkey solutions for box and P-beams, integrating high-frequency or laser welding directly into the roll forming process. This creates a continuous, automated workflow that produces structurally superior, closed-section beams with clean, strong welds, ready for high-load applications in pallet racking and storage systems.

Auto P-beams Roll Forming Line Process

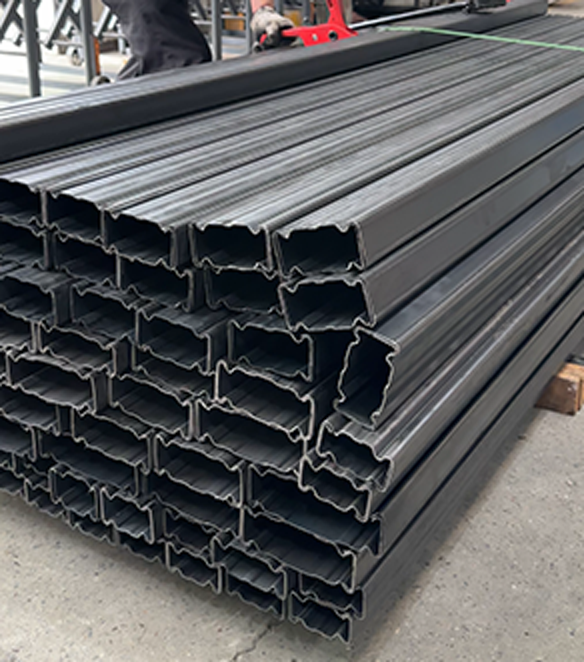

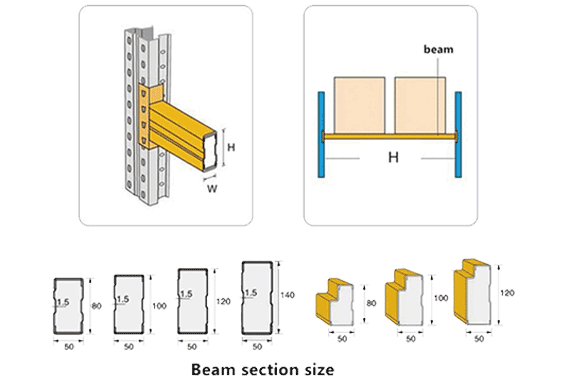

Related P-beams& box beams Cases Display

We can customize according to your requirements based on the load-bearing capacity, dimensions, and specifications needed for shelving P-beams & box beams. Here is a showcase of shelving customizations we have made for shelving factories.

Industrial Solutions, Forged by ARMDAX

Our production lines are not just assemblies of standard parts; they are integrated systems featuring advanced technologies designed to maximize your productivity, flexibility, and profitability.

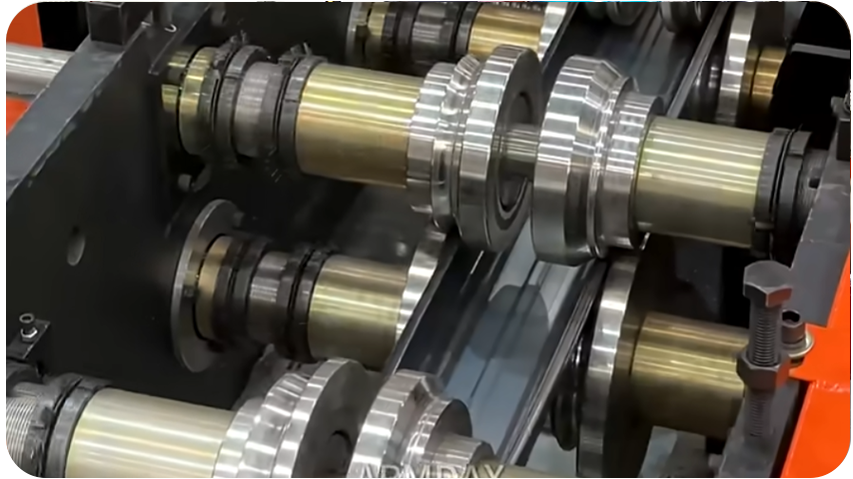

Precision Roll Forming

This is the heart of our system. A series of meticulously engineered rollers gradually bend the metal into your exact profile. This cold forming process enhances material strength while maintaining tight dimensional tolerances.

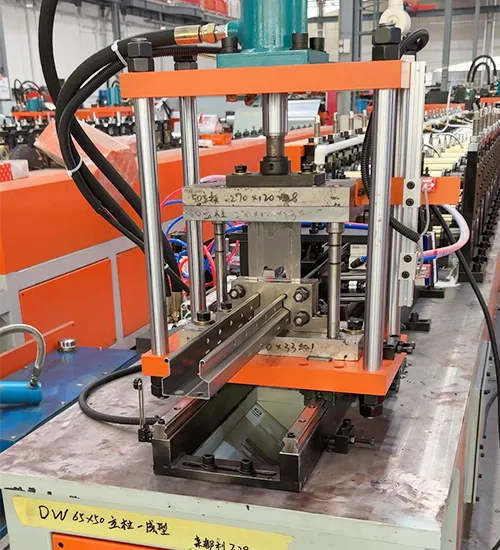

Automated Cut & Snap-Lock Beam Technology

As the box beam is continuously formed, a synchronized automated cut-off saw delivers a perfectly square, burr-free cut without stopping the line. This guarantees dimensional accuracy and a flawless finish. Immediately after cutting, the beam is notched and formed to seamlessly snap-lock onto the upright. This creates a rock-solid connection that's fast to assemble and incredibly strong.

The Final Form: Roll Forming

Witness the moment raw steel transforms into structural strength. In the final stands of our roll forming line, the open channel is seamlessly closed into a perfect high-strength Box Beam making machine. This critical stage ensures: Unmatched Rigidity: A closed-section design provides superior load-bearing capacity. And Perfect Weld Seam: Precision rollers create a clean, consistent seam for maximum structural integrity.

Engineered for Peak

Performance and Precision

Every component and parameter of our production line is designed and specified to deliver consistent, high-quality output.

| Product Material: | Material Thickness: |

| Product Width Range: | Margin of error: |

| Drive System: | Form speed: |

| Control System: | Roller material: |

Download Full Technical Proposal

Download Full Technical ProposalYou Might Also Like

Ready to Optimize Your Production?

FAQS

Q: Can ARMDAX customize roll forming machines for storage racking profiles?

A:

Yes. ARMDAX provides customized racking roll forming machines based on load requirements, profile thickness, hole patterns, and international racking standards, ensuring high precision and repeatability.

Q: What types of racking roll forming machines does ARMDAX supply?

A:

ARMDAX supplies heavy-duty racking roll forming machines for pallet racking, selective racking, drive-in racking, and warehouse storage systems, with optional inline punching and servo cutting systems.

Q: What is your after-sales repair policy about cold roll forming machines?

A:

We provide a one-year warranty for the entire machine. For key components such as the main unit, servo motors, and CNC controllers—excluding consumable parts (tools) from warranty coverage—if any non-human-caused malfunction occurs, we will immediately ship replacement parts free of charge via DHL/FedEx.

Q: What is the maximum material thickness and width your roll forming machines can handle?

A:

ARMDAX roll forming machines are built to handle a wide range. Typically, we work with material thicknesses from 0.2mm to 5 mm and coil widths can be adjustable. However, specific capabilities depend on the profile design and material strength. Our engineers will provide exact specifications after reviewing your requirements.