About Electrical Products Roll Forming Line

We design and manufacture precision roll forming machines for the electrical industry. Produce cable trays, electrical enclosures, raceways, busbars, and conduits with high efficiency, accuracy, and material savings. Get a custom solution for your profile.

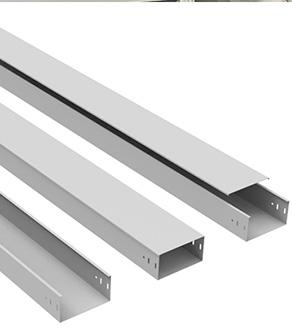

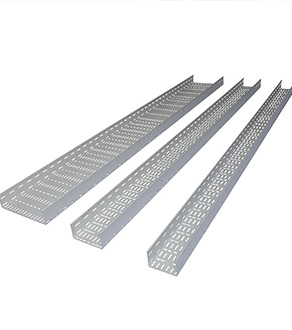

Automated Production Lines for Cable Trays & Ducts

Our turnkey systems are designed for the efficient production of perforated and solid-bottom cable trays. Integrating high-speed punching and roll forming, these lines produce strong, consistent profiles in various sizes. Achieve stable, fast, and precise mass production for electrical infrastructure and data center applications..

Automated Roll Forming Production Line Process

Show the Cable Trays & Ducts Cases We Made

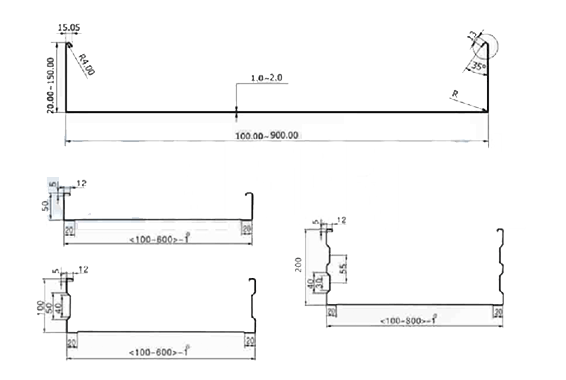

We can customize according to your requirements based on the load-bearing capacity, dimensions, and specifications needed for Cable Trays & Ducts. Here is a showcase of customizations we have made for cable tray factories.

Your Roll Forming Machine Custom Expert

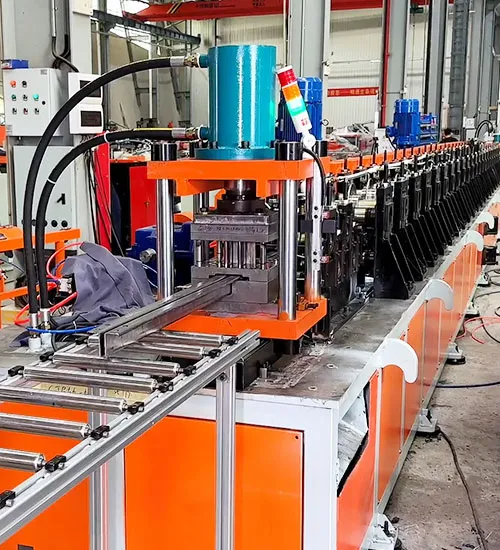

Our production lines are not just assemblies of standard parts; they are integrated systems featuring advanced technologies designed to maximize your productivity, flexibility, and profitability.

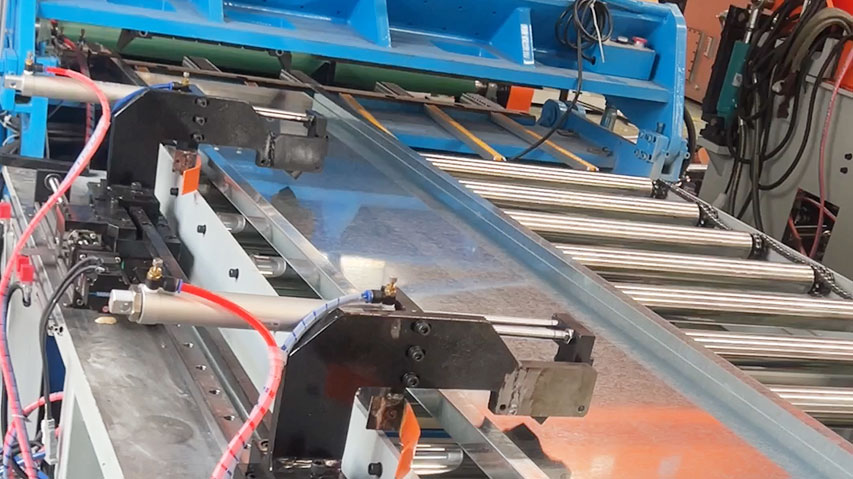

Automated Cutting & Bending

Witness a fully automated journey from coil to finished vanity component. Our integrated line features precision auto-cutting and bending that eliminates manual handling and guarantees flawless results.

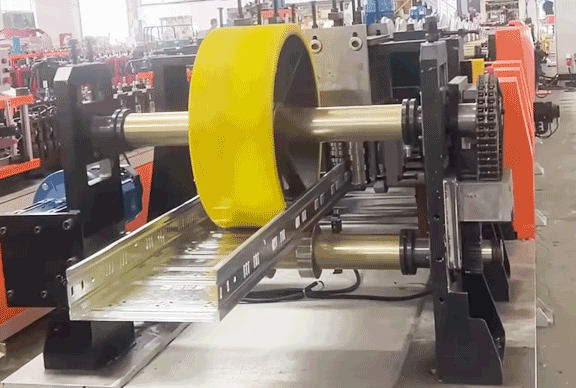

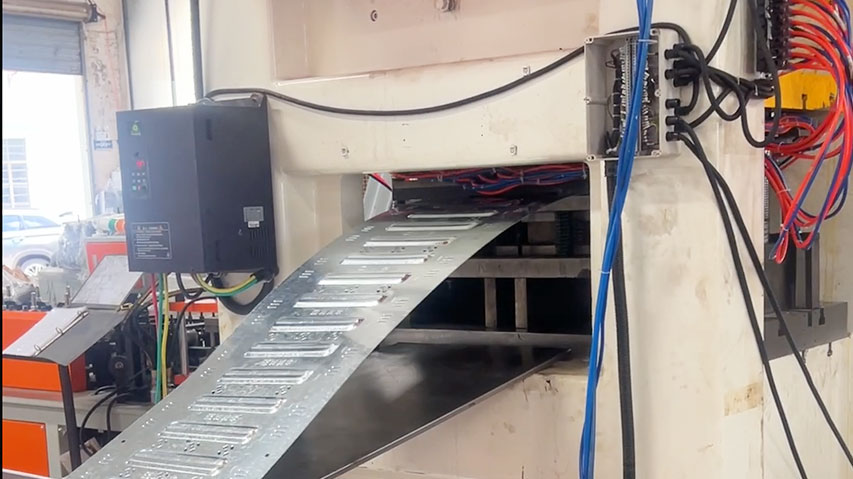

High Speed Punching System

Our integrated high-speed punching technology is the game-changer your line needs, delivering unmatched competitive advantages: Drastically reduce part cycle times. Achieve more hits per minute and maximize your output like never before. Ensure every hole, notch, or emboss is perfectly placed, part after part. Eliminate costly errors and achieve flawless product consistency. And seamlessly integrated with your roll forming line, it enables continuous, uninterrupted production.

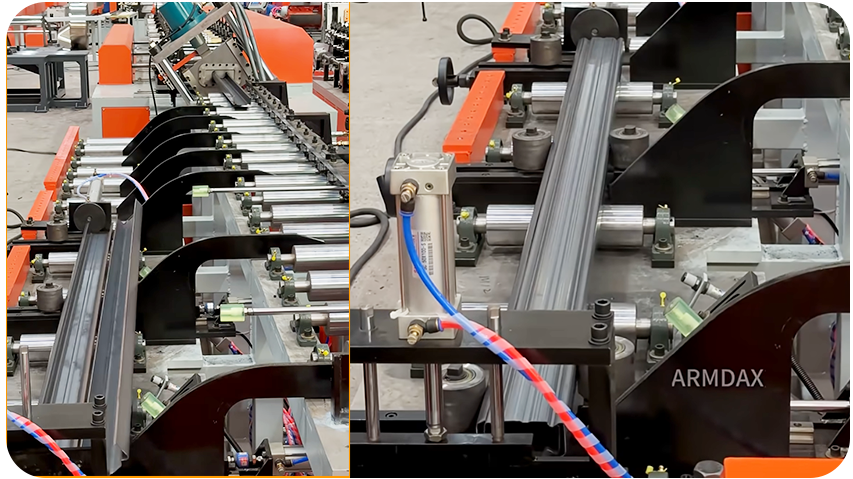

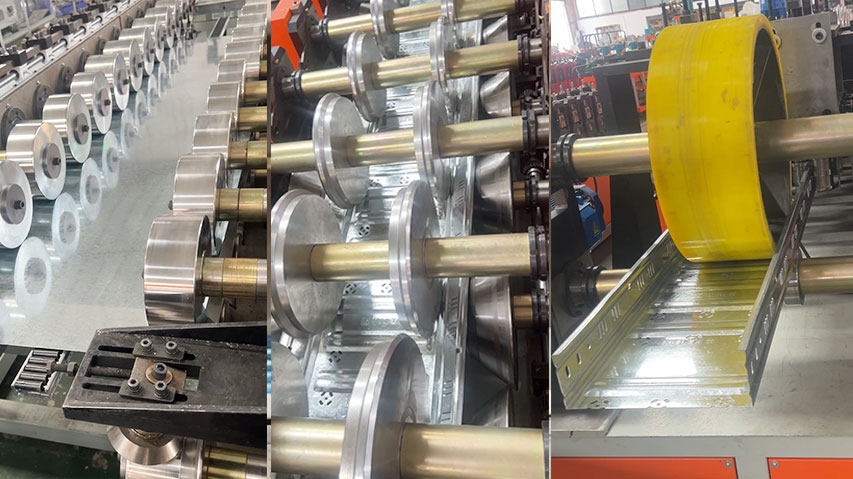

The Final Form: Roll Forming

Witness the moment raw steel transforms into structural strength. In the final stands of our roll forming line, the open channel is seamlessly closed into a perfect high-strength cable trays.This critical stage ensures: Unmatched Rigidity: A closed-section design provides superior load-bearing capacity. And Perfect Weld Seam: Precision rollers create a clean, consistent seam for maximum structural integrity.

Engineered for Peak

Performance and Precision

Every component and parameter of our production line is designed and specified to deliver consistent, high-quality output.

| Product Material: | Material Thickness: |

| Product Width Range: | Margin of error: |

| Drive System: | Form speed: |

| Control System: | Roller material: |

Download Full Technical Proposal

Download Full Technical ProposalYou Might Also Like

Ready to Optimize Your Production?

FAQS

Q: Why choose ARMDAX as your roll forming machine supplier in China?

A:

As an experienced China roll forming machine supplier, ARMDAX combines competitive factory pricing, strict quality control, advanced CNC machining, and professional export service, helping global customers reduce cost while ensuring stable machine performance.

Q: What materials can ARMDAX roll forming machines process?

A:

ARMDAX roll forming machines are designed for various metal materials, including galvanized steel, PPGI, stainless steel, aluminum, carbon steel, and high-strength steel coils, suitable for construction, infrastructure, and industrial applications.

Q: How much does a roll forming machine cost ?

A:

Different industries and different product sizes will affect the price of the machine. We customize solutions based on the your drawings and then calculate the price. We have a professional set of customization and production processes. Do you want to know the price of a roll forming machine , click this blogs maybe can help you understand.

Q: Can your roll forming machine form both steel and aluminum?

A:

Yes, most of our standard models can form both galvanized steel and aluminum coils. The produce materials with thicknesses ranging from 0.2mm to 5mm,and have the thickness adjustment . Please consult our engineers for your specific material requirements

Q: Do you provide installation and training?

A:

Yes, we provide detailed installation manuals and video guides. We also offer optional overseas engineer dispatch for on-site installation and training, with all costs (travel, accommodation) quoted separately.