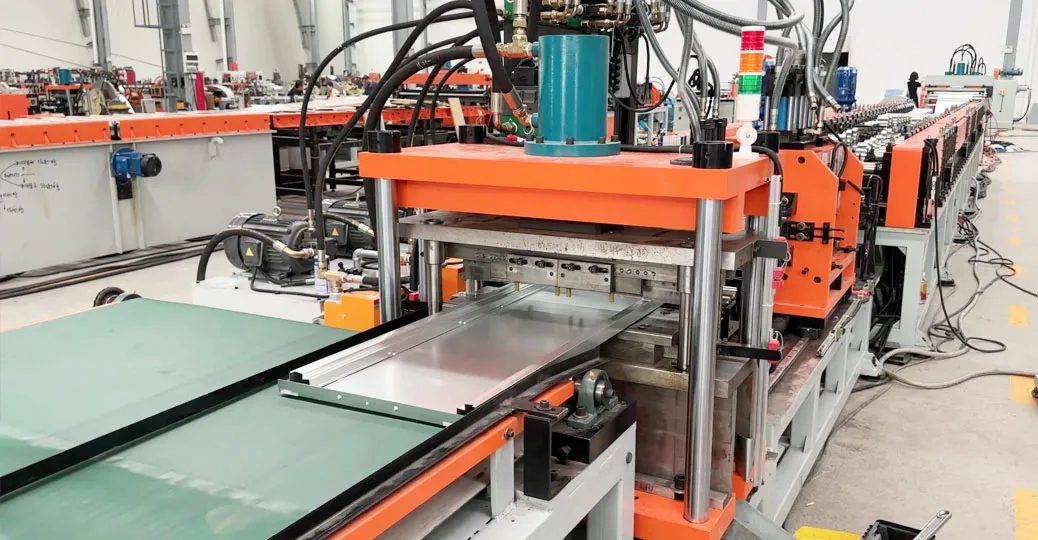

As a Shelf Factory Owner, Should You Buy a Roll Forming Machine?

Aug 27, 2025

Read:227

Source: Armdax

As a shelf factory owner or manager, you're constantly balancing quality, cost, and delivery times. If you're still relying on manual bending, purchasing pre-formed profiles, or struggling with outdated equipment, you've likely asked yourself: Is investing in our own roll forming machine for shelf factory the key to unlocking our growth?

The short answer is yes, for most growing shelf manufacturers, it is a transformative investment. This article isn't just a "yes" — it's a clear-eyed analysis of the benefits, costs, and key considerations to help you decide if it's the right move for your factory.

The Problem: The Hidden Costs of Your Current Production

Before looking at the solution, let's quantify the pain points:

High Outsourcing Costs: Purchasing pre-cut and pre-formed channels and beams from a supplier includes their profit margin.

Inconsistent Quality: Manual processes or inconsistent supplier quality lead to variations in profile dimensions, causing assembly difficulties and a weaker final product.

Production Bottlenecks: You can't control the lead time of your raw materials, making you reactive instead of proactive.

Limited Customization: Relying on standard profiles from suppliers restricts your ability to offer unique, high-margin shelf designs to your clients.

Sky-High Labor Costs: Manual bending is slow, labor-intensive, and prone to errors, tying up your skilled workers on repetitive tasks.

The Solution: How a Roll Forming Machine Directly Addresses These Issues

Bringing roll forming in-house puts you in the driver's seat. Here’s how it directly benefits a shelf factory:

1. Slash Your Raw Material Costs

Buying raw steel coil is significantly cheaper than buying pre-formed profiles. By forming your own C-purlins, U-channels, and box beams, you cut out the middleman and dramatically reduce your cost-per-unit.

2. Achieve Unbeatable Consistency & Quality

Every beam and post coming off your line will be identical. This precision ensures:

Faster, easier assembly of your final shelving units.

A stronger and more reliable product for your customers.

A professional finish that enhances your brand reputation.

3. Take Control of Your Production Schedule

No more waiting for supplier deliveries. With a coil of steel and your own machine, you become the master of your own production timeline. Produce exactly what you need, when you need it, to meet urgent orders and scale up effortlessly.

4. Unlock Design Freedom & Customization

Want to create a unique, heavy-duty beam for a specific client? Need to quickly switch between different profile designs? An in-house roll forming machine gives you the flexibility to innovate and capture niche markets that your competitors can't.

5. Drastically Reduce Labor Dependence

A single, semi-automated roll forming line can replace multiple manual bending stations. One operator can manage the entire process from decoiling to cutting, freeing up your team for higher-value tasks like assembly, welding, and quality control.

Key Considerations Before You Buy A Roll Forming Machine

Not all roll forming machines are created equal. When evaluating, ask these questions:

What profiles do I need? (e.g., C-Z Purlins, Decking, Box Beams for uprights).

What is my required output? (Meters per hour/shift).

What material type and thickness will I be forming? (e.g., 0.8mm - 2.0mm galvanized steel).

Do I need auxiliary equipment? (e.g., an automatic decoiler, pre-punching station, or stacking conveyor).

The ROI Calculation: Is It Worth It?

Let's break down the financials with a simplified example:

Current Cost: You buy 10,000 meters of pre-formed C-purlin per month at $1.5/meter → $15,000/month.

New Cost with Machine: You buy steel coil to produce 10,000 meters at $0.9/meter → $9,000/month.

Monthly Direct Savings: $6,000.

Even with a machine payment plan, the savings often pay for the investment in a surprisingly short period—often 12 to 24 months. When you factor in reduced labor, fewer errors, and the ability to win more business through faster turnaround and customization, the ROI becomes undeniable.

Conclusion: The Verdict for Shelf Factories

For a shelf factory aiming to reduce costs, control quality, and scale production, investing in a roll forming machine is not just an expense—it's a strategic move to secure your competitive advantage.

The initial investment is outweighed by the long-term gains in profitability, efficiency, and market agility. It's the difference between being a workshop that assembles shelves and a fully-integrated manufacturing powerhouse.

Still Unsure if It's the Right Time for Your Business?

Contact us for a free, no-obligation productivity analysis. Our experts will review your current production process and help you calculate the potential ROI specifically for your factory. Let's build the future of your shelf manufacturing, together.

Table of Contents