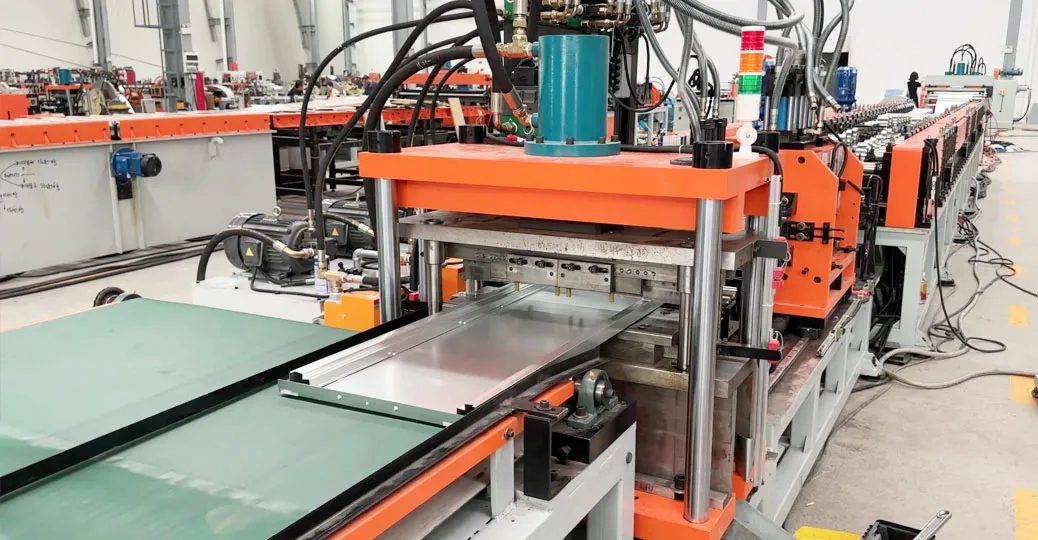

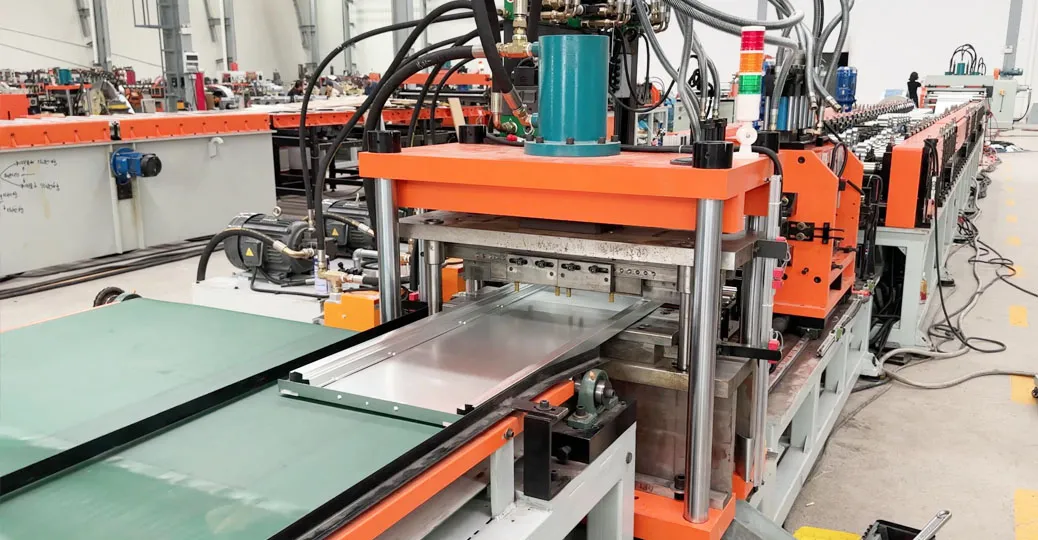

How a Shelf Panel Roll Forming Machine Can Revolutionize Your Storage Solution Production

Nov 08, 2025

Read:176

Source: Armdax

In the competitive world of storage and shelving manufacturing, efficiency isn't just a goal—it's the key to profitability and growth. If you're still relying on manual bending, outsourcing panels, or struggling with inconsistent quality, you're facing hidden costs and production bottlenecks.

The solution? Investing in a dedicated shelf panel roll forming machine. This isn't just another piece of equipment; it's a strategic upgrade that can fundamentally transform your factory's output. Let's explore the five key ways it drives efficiency.

1. Slash Storage Solution Manufacturing Time

The Problem: Traditional methods like manual press braking are slow and labor-intensive. Producing large orders can take days, creating delays and limiting your capacity to take on more work.

The Solution: A roll forming machine is a continuous production powerhouse.

High-Speed Output: Produce finished shelf panels at linear speeds of 20-30 meters per minute or more.

Uninterrupted Flow: The process from steel coil to cut-to-length, punched panel is fully automated. This dramatically shortens lead times, allowing you to fulfill large and urgent orders with ease.

2. Roll Forming Machine Can Reduce Your Costs

Efficiency translates directly to your bottom line. A roll forming machine targets multiple cost centers at once.

Lower Material Costs: Buying raw steel coil is significantly cheaper than purchasing pre-formed or pre-cut panels. You immediately cut out the supplier's markup.

Reduce Labor Costs: One automated line replaces multiple manual bending stations. A single operator can manage the entire process, freeing up your skilled workforce for higher-value tasks like assembly and welding.

Minimize Material Waste: Precision forming and programmed cutting lead to near-zero scrap. You use almost every meter of coil you pay for, maximizing material utilization.

3. Achieve Unbeatable, Consistent Quality

In shelving, consistency is critical for easy assembly and structural integrity. Variations in panel dimensions lead to assembly headaches and weak final products.

Precision Engineering: Every panel that comes off the line is identical, with precise bends and consistent dimensions. This ensures perfect, seamless assembly every time.

Eliminate Human Error: Automated processes remove the variations and flaws introduced by manual labor.

Integrated Punching: Roll forming lines can include in-line punching stations, ensuring that clip holes and reinforcing ribs are perfectly placed on every panel, further speeding up assembly.

4. Gain Unmatched Production Flexibility

Market demands change. You need to produce various panel widths, lengths, and designs without costly downtime.

Quick-Change Tooling: Switch between different shelf panel profiles (e.g., different rib patterns or widths) in minutes, not hours. This drastically reduces downtime and allows for high-mix production.

Customization at Will: Easily produce custom panels for specialized clients, opening up new, high-margin market segments that are inaccessible to competitors using standard components.

5. Streamline Your Entire Workflow

A shelf panel roll forming machine becomes the core of a streamlined, integrated production cell.

In-Line Operations: Integrate auxiliary stations for punching, notching, and embossing directly into the line. This eliminates secondary operations and handling.

Simplified Inventory Management: You only need to stock raw steel coil, simplifying your supply chain and reducing inventory costs and space.

Reduced waste

New business opportunities from customization

...means that a shelf panel roll forming machine doesn't just improve efficiency—it fundamentally upgrades your business model and competitive edge.

Ready to See the Difference in Your Factory?

Stop letting inefficient production hold you back. Contact us at ARMDAX today for a free, no-obligation consultation. Our experts will analyze your current process and provide a customized ROI analysis to show you exactly how our roll forming machines can power your growth and profitability.

Table of Contents