Roll Forming Machine For Outdoor Construction Industries

Power your outdoor construction projects with our high-strength roll forming machines. Engineered for durability, they efficiently produce precise, long-lasting panels and components for solar, cladding, fencing, and structural systems.

Solar Mounting & Unistrut Channel Cold Roll Forming Machine

Engineered for the solar industry, ARMDAX roll forming machine produces high-strength, precise mounting brackets with unmatched efficiency. Build the reliable foundation for any solar array, from rooftop to utility-scale farms.

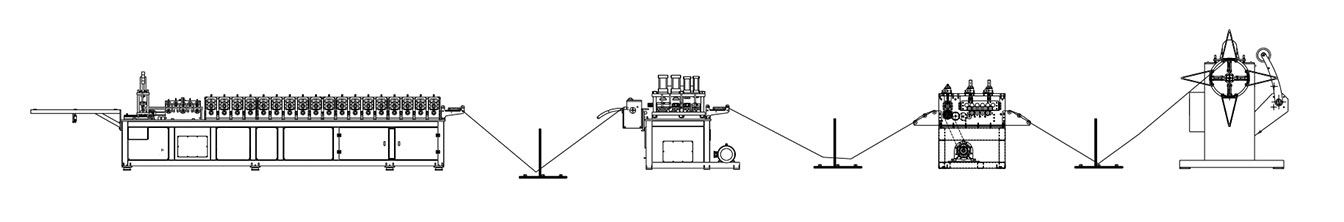

Solar Mounting Roll Forming Making Line Process

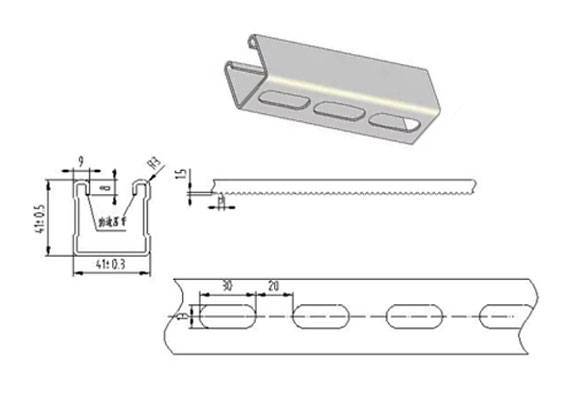

Show you the Unistrut Bracket Cases

We can customize according to your requirements based on the load-bearing capacity, dimensions, and specifications needed for solar brackets. Here is a showcase of customizations we have made for solar system factories.

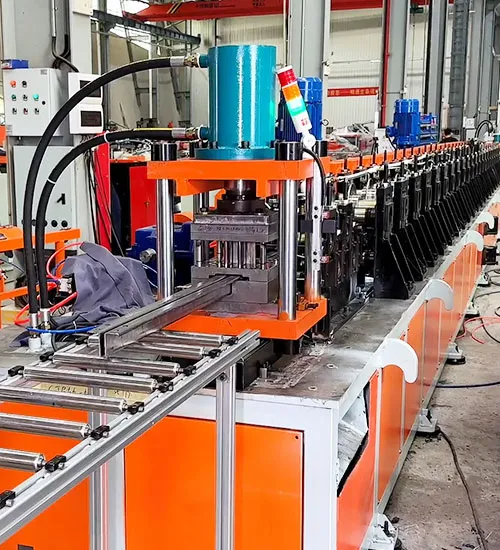

ARMDAX Excellent Roll Forming Technology

Our production lines are not just assemblies of standard parts; they are integrated systems featuring advanced technologies designed to maximize your productivity, flexibility, and profitability.

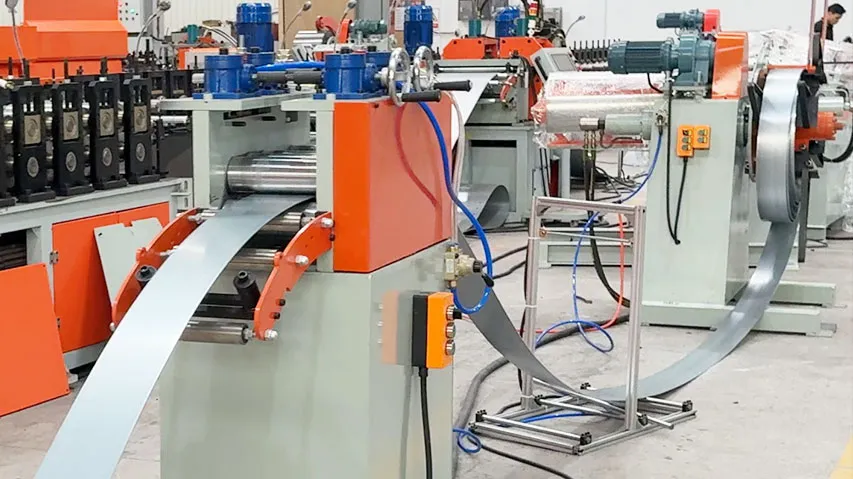

Coil Feeding & Leveling System

Every great roll-formed product begins with a perfect start. Our automated coil feeding and precision leveling machines are the unsung heroes of your solar brackets production line, ensuring consistent quality from the very first meter.

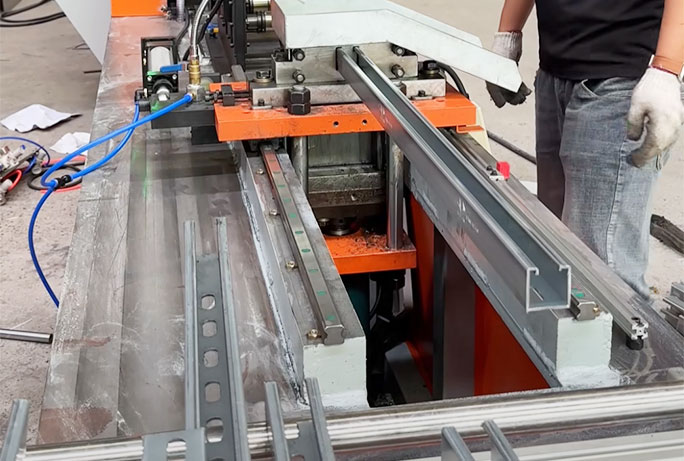

High Speed Punching System

ARMDAX integrated high-speed punching technology is the game-changer your line needs, delivering unmatched competitive advantages: Drastically reduce part cycle times. Achieve more hits per minute and maximize your output like never before. Ensure every hole, notch, or emboss is perfectly placed, part after part. Eliminate costly errors and achieve flawless product consistency. And seamlessly integrated with your roll forming line, it enables continuous, uninterrupted production.

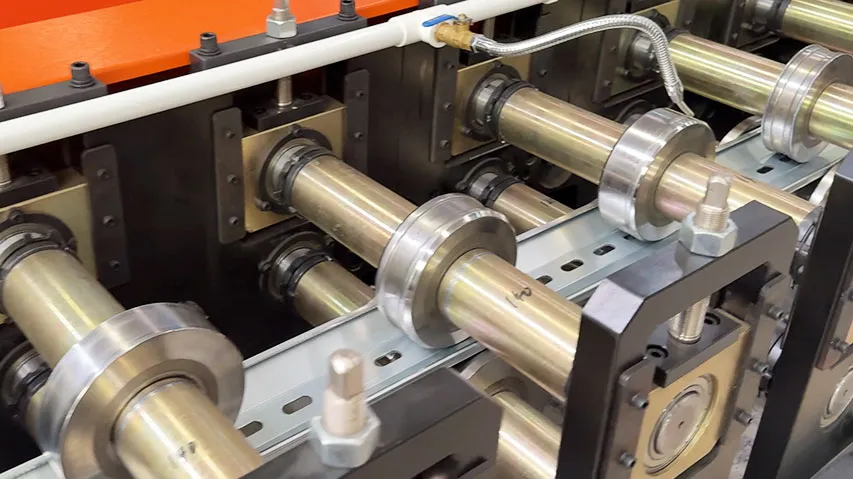

Advanced Roll Forming System

Critical components are manufactured to the highest standards. Rollers are precision-machined on CNC lathes. Main shafts, are made from Cr12MoV alloy steel, tempered and precision-ground for maximum rigidity. The main frame side plates are machined from solid steel plates in a single setup on a CNC machining center to ensure perfect alignment.

Engineered for Peak

Performance and Precision

Every component and parameter of our production line is designed and specified to deliver consistent, high-quality output.

| Product Material: | Material Thickness: |

| Product Width Range: | Margin of error: |

| Drive System: | Form speed: |

| Control System: | Roller material: |

Download Full Technical Proposal

Download Full Technical ProposalYou Might Also Like

Ready to Optimize Your Production?

FAQS

Q: How long is the delivery time for ARMDAX roll forming machines?

A:

The production time for a standard roll forming machine is usually 30–45 days, while custom roll forming production lines may require 45–60 days, depending on profile complexity and automation level.

Q: How much does a roll forming machine cost ?

A:

Different industries and different product sizes will affect the price of the machine. We customize solutions based on the your drawings and then calculate the price. We have a professional set of customization and production processes. Do you want to know the price of a roll forming machine , click this blogs maybe can help you understand.

Q: What is the maximum material thickness and width your roll forming machines can handle?

A:

ARMDAX roll forming machines are built to handle a wide range. Typically, we work with material thicknesses from 0.2mm to 5 mm and coil widths can be adjustable. However, specific capabilities depend on the profile design and material strength. Our engineers will provide exact specifications after reviewing your requirements.

Q: Can your roll forming machine form both steel and aluminum?

A:

Yes, most of our standard models can form both galvanized steel and aluminum coils. The produce materials with thicknesses ranging from 0.2mm to 5mm,and have the thickness adjustment . Please consult our engineers for your specific material requirements