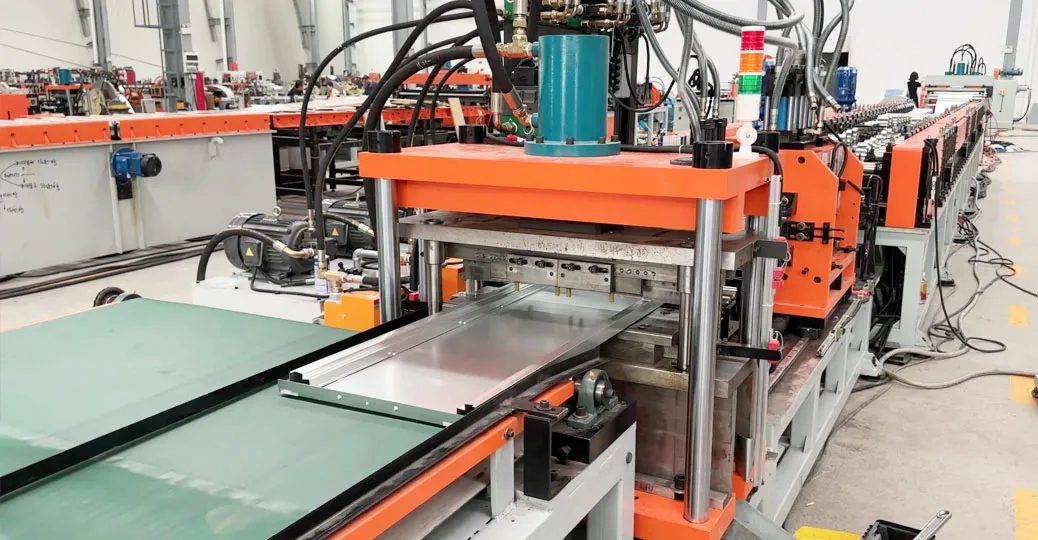

How a Storage Rack Roll Forming Machine Can Revolutionize Your Production Efficiency

Oct 25, 2025

Read:273

Source: Armadx

In the competitive world of storage solutions, efficiency isn't just a goal—it's the key to survival and growth. If your factory is still relying on manual bending, outsourcing profiles, or struggling with outdated equipment, you're facing hidden costs and missed opportunities.

The solution? Bringing production in-house with a storage rack roll forming machine. This isn't just an equipment purchase; it's a strategic investment that can fundamentally transform your operation. Here’s how.

1. Slash Production Time from Days to Hours

The Problem: Traditional manufacturing methods like manual bending or purchasing pre-formed components are slow. They create bottlenecks, leaving you waiting and unable to fulfill large or urgent orders.

The Solution: A roll forming machine is a continuous production powerhouse.

High-Speed Output: Produce finished beams, uprights, and decking at linear speeds of 20-30 meters per minute or more.

Uninterrupted Flow: From coil to cut-to-length product, the process is seamless. This dramatically shortens your lead times, allowing you to respond to market demands with agility.

2. Drastically Reduce Your Operational Costs

Efficiency is directly tied to your bottom line. A roll forming machine attacks costs on multiple fronts.

Lower Material Costs: Buying raw steel coil is significantly cheaper than purchasing pre-formed C-purlins or box beams. You cut out the supplier's markup.

Reduce Labor Costs: One automated line replaces multiple manual bending stations. One or two operators can manage the entire process, freeing up your skilled labor for higher-value tasks like assembly and welding.

Minimize Material Waste: Precision forming and programmed cutting lead to near-zero scrap material. You use almost every meter of coil you pay for.

3. Achieve Unbeatable, Consistent Quality

In storage racks, structural integrity is non-negotiable. Inconsistencies in component dimensions lead to assembly problems and weak final products.

Precision Engineering: Every beam and upright that comes off the line is identical, with tolerances within ±0.1mm. This ensures perfect, seamless assembly every time.

Eliminate Human Error: Automated processes remove the variations and flaws introduced by manual labor.

Superior Product Strength: The consistent cold-forming process creates a stronger, more reliable product that your customers can trust.

4. Gain Unmatched Production Flexibility

Market trends change. Customer demands evolve. Your machinery needs to keep up.

Quick-Change Tooling: Switch from producing a 100mm beam to a 150mm decking profile in minutes, not hours. This drastically reduces downtime and allows for high-mix, low-volume production.

Customization at No Extra Cost: Easily produce custom profiles for specialized clients, opening up new, high-margin market segments that are inaccessible to competitors using standard components.

5. Streamline Your Entire Workflow

A roll forming machine becomes the core of a streamlined, integrated production cell.

In-Line Operations: Integrate auxiliary stations for punching, notching, and embossing directly into the line. This eliminates secondary operations and handling.

Simplified Inventory Management: You only need to stock raw steel coil, simplifying your supply chain and reducing inventory costs and space.

The Bottom Line: It's an Investment That Pays for Itself

While there is an initial investment, the ROI is clear and compelling. The combination of:

Faster production speeds

Lower material and labor costs

Reduced waste

New business opportunities from customization

...means that a storage rack roll forming machine doesn't just improve efficiency—it fundamentally upgrades your business model and competitive edge.

Ready to See the Difference?

Don't just read about efficiency—experience it. Contact us at ARMDAX today for a free consultation. Our experts will analyze your current process and provide a customized ROI analysis to show you exactly how a roll forming machine can power your growth.

Table of Contents