Choose the Right C Channel Roll Forming Machine For A Smart Investment

Jan 09, 2026

Read:169

Source: Armdax

For global buyers in construction, infrastructure, and manufacturing, sourcing reliable roll forming machinery is a strategic decision. Among the key How to Choose the Right C Channel Roll Forming Machine: A Smart Investment for Your Factory

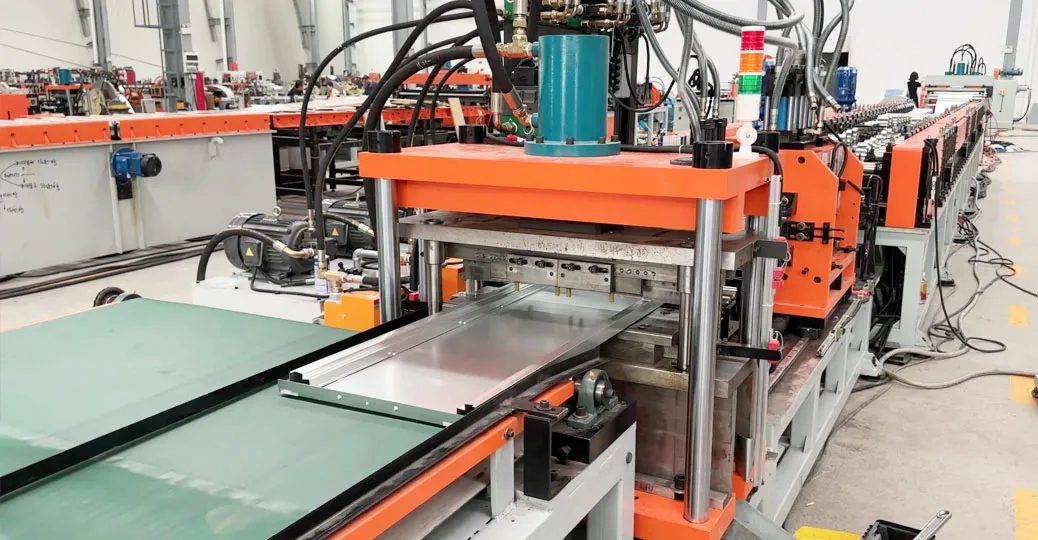

In the construction and building materials industry, C channels are essential structural components used in framing, support systems, and countless industrial applications. As demand grows, many factories reach a critical point where manual or semi-automated production can no longer meet output targets. This is when investing in an efficient, intelligent C channel roll forming machine becomes crucial — not only to boost capacity but also to improve factory profitability, ensure consistent quality, and reduce long-term labor costs.

With the rapid advancement of technology and intelligent manufacturing in China, the roll forming machinery sector has matured significantly. Today, Chinese manufacturers offer optimized, automated solutions that bring precision, speed, and smart operation to metal forming processes. These innovations enable sheet metal and construction material producers to scale efficiently while maintaining high standards.

As a pioneer and industry leader in roll forming technology in China, ARMDAX has deep expertise in designing and manufacturing high-performance C channel roll forming machines. With years of specialized experience, proprietary technical solutions, and a customer-focused approach, ARMDAX helps factories make informed decisions — delivering not just machines, but true production optimization.

Key Considerations When Choosing a C Channel Roll Forming Machine

1. Assess Your Production Requirements

Output volume – Determine daily/monthly production targets.

Material specifications – Include steel grade, thickness range, coating type (galvanized, pre-painted, etc.), and width.

Channel dimensions – Flange and web sizes, tolerances, and possible profile variations.

Future flexibility – Consider if you might need to produce different profiles later.

2. Level of Automation & Intelligence

Look for features such as:

PLC control with touchscreen interface

Automatic feeding and cutting systems

Quick-change tooling designs

Real-time monitoring and fault diagnostics

Data tracking and production reporting

Intelligent systems reduce manual intervention, improve accuracy, and minimize waste.

3. Machine Durability & Precision

Robust frame construction and high-quality forming rolls ensure long-term stability.

Precision-ground gears and hardened rollers maintain profile accuracy over high-volume runs.

Reliable brand-name electrical and hydraulic components reduce downtime.

4. Manufacturer’s Experience & Support

Choose a supplier with a proven track record in C channel applications.

Evaluate their ability to provide customized solutions – not just standard machines.

Check availability of technical support, training, spare parts, and after-sales service.

5. Energy Efficiency & Safety

Modern servo-driven systems save energy compared to traditional setups.

Safety guards, emergency stops, and compliance with international standards (CE, etc.) are essential.

6. Total Cost of Ownership

Look beyond the initial price. Consider:

Maintenance costs

Tooling life and replacement

Energy consumption

Labor savings over time

A slightly higher investment in a reliable, efficient machine often pays back quickly through higher productivity and lower operating costs.

Why ARMDAX Stands Out in C Channel Roll Forming Technology

ARMDAX combines engineering excellence with practical industry insight to provide solutions that truly enhance factory performance.

Deep Application Experience: We understand the real-world challenges in producing C channels for construction, storage systems, furniture, and industrial framing. Our machines are designed to handle various materials and specifications with consistency.

Smart & Adaptive Designs: Our roll forming lines can integrate punching, notching, embossing, and automatic stacking — all synchronized for seamless operation. The intelligent control system allows easy parameter adjustments and stores settings for different products.

Focus on ROI: We help you calculate not only machine cost, but also the return on investment through increased output, reduced scrap, and labor savings. Our goal is to make your production more competitive.

End-to-End Support: From initial consultation and layout design to installation, training, and ongoing technical support, ARMDAX partners with you for the long term. We provide comprehensive operation and maintenance guidance.

Custom Engineering Welcome: Have a special requirement or an existing production challenge? We thrive on creating tailored solutions. Send us your drawings or specifications for a detailed assessment and proposal.

Make the Smart Choice for Your Factory’s Future

Upgrading to an automated C channel roll forming machine is a strategic move that boosts capacity, improves product uniformity, and strengthens your market position. With China’s manufacturing expertise now at a world-class level, choosing the right partner ensures you gain access to advanced technology without compromising on reliability or value.

ARMDAX is committed to delivering high-quality, high-efficiency roll forming systems backed by meaningful engineering support. Let us help you transform your production with smarter technology and deeper insight.

Welcome to send us your drawings or requirements for a customized solution quote. Contact us today to discuss how we can optimize your C channel production together.

Table of Contents