ARMDAX AF1200 Panel Bender With Superior Performance

Jan 16, 2026

Read:815

Source: Armdax

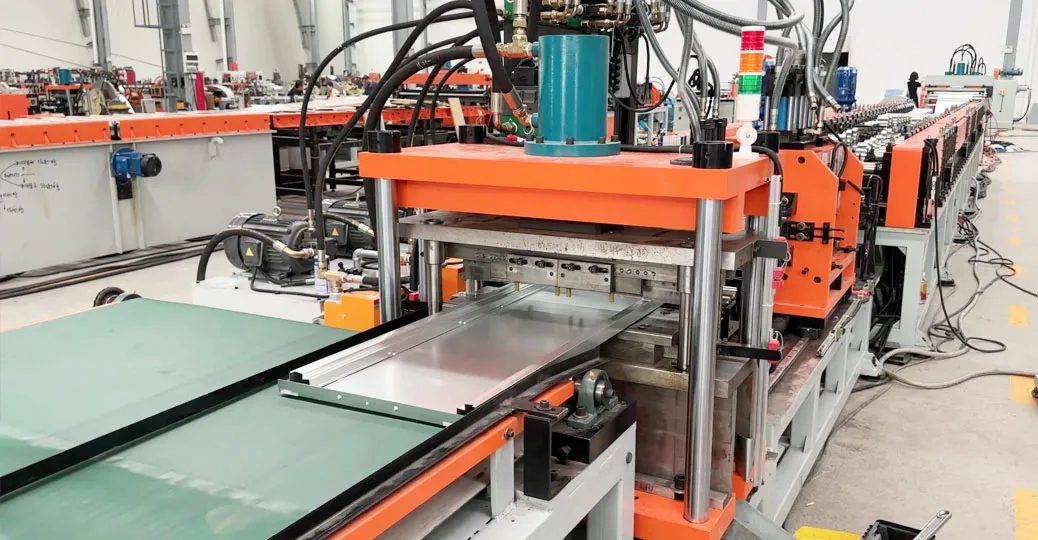

The ARMDAX AF1200 panel bender is a leading-edge bending center developed by our company with independent intellectual property rights. This machine integrates advanced design concepts, rigorous engineering, and high-quality components to deliver outstanding rigidity, precision, and reliability in sheet metal forming. By combining welded high-strength steel construction with sophisticated finite element analysis and precision drive systems, the AF1200 sets a new standard for efficient, accurate, and durable panel bending.

AF1200 panel bender With Independent IP and Innovative Concept

The AF1200 panel bender is one of our flagship machines built on proprietary technology and independent intellectual property. Its design philosophy addresses critical industry challenges with a novel approach to bending center architecture, control, and integration. This IP-backed innovation enables unique performance advantages and a clear differentiation in the competitive market.

Welded High-Strength Steel Structure

The entire machine is constructed from welded high-strength steel plates, providing exceptional rigidity and strength. This robust frame minimizes flex under heavy loads, ensuring stable performance even in demanding production environments.

The welded construction contributes to durable long-term accuracy and reduced maintenance needs.

FEM-Optimized Design with 3D Engineering

The AF1200 leverages 3D computer-aided design (CAD) and finite element analysis (FEA) using ANSYS for optimization. Finite element analysis identifies and mitigates stress concentrations, improves stiffness, and optimizes material distribution.

The result is a machine that combines efficient weight management with maximum structural integrity, enhancing both performance and lifespan.

Dedicated High-Load Ball Screw and Guideway System

The machine uses specialized high-load ball screws and precision guideways designed for high load capacity. A premium guideway system provides smooth, accurate motion with reduced friction and wear. The combined effect is superior positioning accuracy, repeatability, and longer service life, even under continuous operation.

Imported Bearings and Premium Components

The AF1200 employs imported bearings to ensure high load tolerance and consistent performance. Quality bearings reduce deflection and vibration, contributing to overall machine rigidity and precision retention. Coupled with high-grade components throughout, the machine demonstrates exceptional reliability in manufacturing environments. Rigidity, Accuracy Retention, and Reliability. Rigidity is engineered into every element of the AF1200, from the frame to the tooling interface. The design emphasizes accuracy retention, maintaining tight tolerances across long production runs. Reliability is a core objective, with components and assembly practices chosen to minimize downtime and maintenance.

Engineering Excellence and Benefits

Superior Structural Rigidity: The welded high-strength steel frame minimizes deformation under load, leading to stable meniscus and bend quality across varying sheet thicknesses and materials.

Precision and Repeatability: High-load ball screws and precision guideways deliver repeatable, high-accuracy bends with low thermal drift and long-cycle reliability.

Optimized for Tough Applications: The AF1200 is designed to handle demanding panel-bending tasks, including complex geometries, tight radii, and large-format panels.

Lifecycle Value: While the upfront investment is competitive, the machine’s durability, lower maintenance, and longer service life translate into lower total cost of ownership over time.

Advanced Design Methodology: The integration of 3D design with ANSYS optimization ensures the machine’s performance is grounded in robust engineering and verified by simulation.

Applications and Performance Scenarios

Automotive exterior panels and body-in-white components requiring precise bending with consistent radii and smooth edge quality.

Aerospace sheet metal fabrications where tight tolerances and repeatability are critical.

HVAC ducting, enclosures, and electrical panels that demand high rigidity and dependable long-term performance.

General metal fabrication shops seeking a high-precision, high-durability bending center for diverse materials and thicknesses.

Why the AF1200 Panel Bender Stands Out

Independent IP Advantage: A uniquely designed bending center protected by our own intellectual property, delivering differentiated capabilities and support.

Structural Integrity: A welded high-strength steel frame provides unparalleled rigidity, enabling precise bends even on challenging jobs.

Design Validation: 3D modeling combined with ANSYS finite element analysis ensures optimized performance before production, reducing risk and accelerating deployment.

High-Quality Motion: Dedicated high-load ball screws and premium guideways deliver stable motion, excellent repeatability, and extended life.

Component Quality: Imported bearings and carefully selected components reduce vibration, wear, and downtime, increasing overall uptime.

Environmental and Operational Considerations

Energy Efficiency: The AF1200’s optimized structure reduces energy losses during actuation and motion, contributing to lower operating costs.

Maintenance Strategy: With a robust design and high-quality components, maintenance intervals are extended, improving plant uptime.

Post-Sales Support: Our team provides comprehensive service and support for installations, calibration, and ongoing optimization to ensure the machine’s long-term performance.

The ARMDAX AF1200 panel bender represents a milestone in bending center technology, combining independently developed IP with a welded high-strength steel structure and mathematical optimization. By embracing 3D design and ANSYS-based FEM analysis, the AF1200 achieves superior rigidity, high-load capacity, precise positioning, and long service life. In short, it is a reliable, accurate, and efficient solution for modern sheet metal fabrication that can meet the most demanding bending tasks with confidence.

Would you like a product datasheet or a comparison table contrasting the AF1200 with competing models in terms of load capacity, accuracy, cycle times, and TCO? If you’re evaluating ROI, I can help estimate potential production gains based on your typical panel sizes, thicknesses, and run volumes. Interested in a virtual tour or a live demonstration of the AF1200’s bending performance on a sample project?

If you share your target applications and typical material parameters, I can tailor a more precise case study or technical briefing to support your procurement or engineering decision process. Would you like me to draft a customized specification sheet or a short case study featuring a real-world implementation of the AF1200?

Welcome to contact us anytime , just send your products details or design drawings . The most comprehensive assessment program to help you better solve production problems and increase output.

Table of Contents