Revolutionize Your Racking Production with ARMDAX Gondola Rack Roll Forming Machines

Dec 12, 2025

Read:227

Source: Armdax

In the competitive world of warehousing and retail storage manufacturing, efficiency and precision are not just goals—they are survival necessities. As the demand for high-quality gondola shelving and heavy-duty storage racks continues to rise, manufacturers need equipment that delivers consistency without compromising on speed.

At ARMDAX, we bring extensive experience in the roll forming industry to your factory floor. We specialize in providing top-tier Gondola Rack Roll Forming Machines designed to transform your production capabilities, offering optimal solutions for every component of a shelving system.

Decades of Expertise in the Racking Industry

Choosing the right machinery partner is critical. ARMDAX is not just a machine supplier; we are experts in the nuances of storage rack production. Our deep understanding of the warehousing and racking industry allows us to engineer machines that address common manufacturing pain points.

Whether you are producing supermarket gondola shelves or heavy-duty warehouse racking, our technology is built on a foundation of industry-specific knowledge, ensuring that every profile produced meets the highest standards of durability and accuracy.

One-Stop Solution for All Racking Components

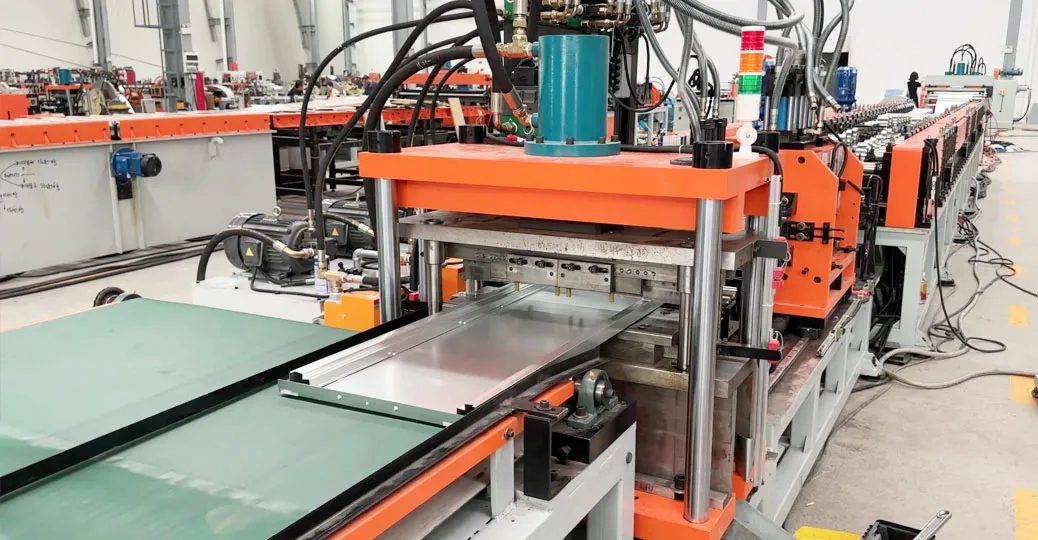

A complete racking system requires various complex profiles. ARMDAX provides a comprehensive suite of roll forming solutions tailored to produce every essential part of a gondola or storage rack system. Our machines are engineered for versatility and precision:

Shelf Panels (Layer Boards): Produce perfectly flat, high-load capacity steel shelves with automated bending and cutting.

Back Panels: High-speed production of solid or perforated back panels that fit seamlessly into uprights.

Uprights (Columns): Heavy-duty roll formers capable of handling thick gauge steel for robust vertical supports, including precise punching for bracket slots.

Beams: Create strong, interlocking beams that ensure the structural integrity of the entire racking unit.

We don't just sell machines; we design customized production lines that fit your specific factory layout and product specifications.

Maximize Efficiency and Minimize Labor Costs

The traditional manufacturing of racking components often involves multiple steps and significant manual labor, leading to bottlenecks and higher costs. ARMDAX roll forming lines are designed to change that.

1. Automated Production

Our fully automated lines integrate punching, roll forming, cutting, and even stacking into a continuous process. This seamless integration means you can go from raw coil to finished product in a single pass.

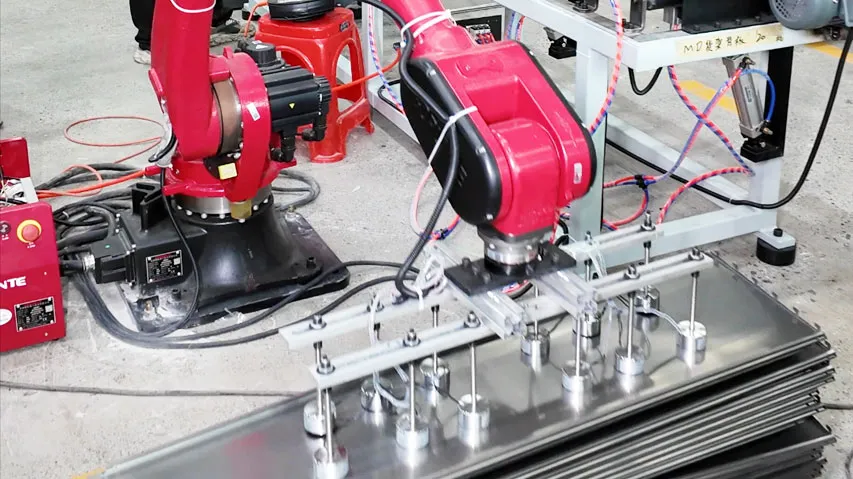

2. Reduced Labor Input

By automating complex tasks, ARMDAX machines significantly reduce the reliance on manual labor. This not only lowers your operational costs but also minimizes the risk of human error, ensuring a uniform product quality that your customers can trust.

3. Skyrocketing Production Speed

Time is money. Our high-speed roll forming technology allows you to meet tight deadlines and large volume orders with ease. Experience a dramatic increase in daily output compared to conventional manufacturing methods.

Elevate Your Manufacturing with ARMDAX

If you are looking to upgrade your racking production line, ARMDAX is your trusted partner. We combine robust engineering with cutting-edge technology to deliver machines that pay for themselves through efficiency and quality.

Contact us today to discuss how we can tailor a Gondola Rack Roll Forming solution for your factory and help you stay ahead in the global market.

Table of Contents